SolderTip #47: How Long Does it Take to Make A Solder Joint

Welcome to the ultimate guide on understanding the duration required to create a solder joint with SolderTip #47. As experts in SEO services, we are committed to providing you with valuable information to help you outrank other websites in search engine rankings.

What is a Solder Joint?

Before we delve into the time it takes to make a solder joint, let's first understand what it actually is. In electronics, a solder joint refers to the permanent connection between two or more metal components using molten solder.

Factors that Influence Soldering Time

The time required to make a solder joint can vary based on several factors. Let's explore these factors in detail:

Surface Preparation:

Properly preparing the surfaces to be soldered is crucial for achieving a strong and reliable solder joint. Depending on the condition of the surfaces, additional time may be needed for cleaning, flux application, and removing oxidation to ensure optimal soldering results.

Component Complexity:

The complexity of the components being soldered can significantly impact the time required. More intricate designs, smaller components, and densely packed circuitry may demand additional time and precision during the soldering process.

Soldering Technique:

The soldering technique employed plays a vital role in determining the time needed to create a solder joint. Different techniques, such as through-hole soldering, surface mount soldering, or reflow soldering, may require varying durations for successful completion.

Soldering Skill:

Experience and expertise in soldering can greatly influence the time it takes to make a solder joint. Highly skilled individuals with extensive knowledge of soldering techniques and best practices can achieve efficient and precise results more quickly.

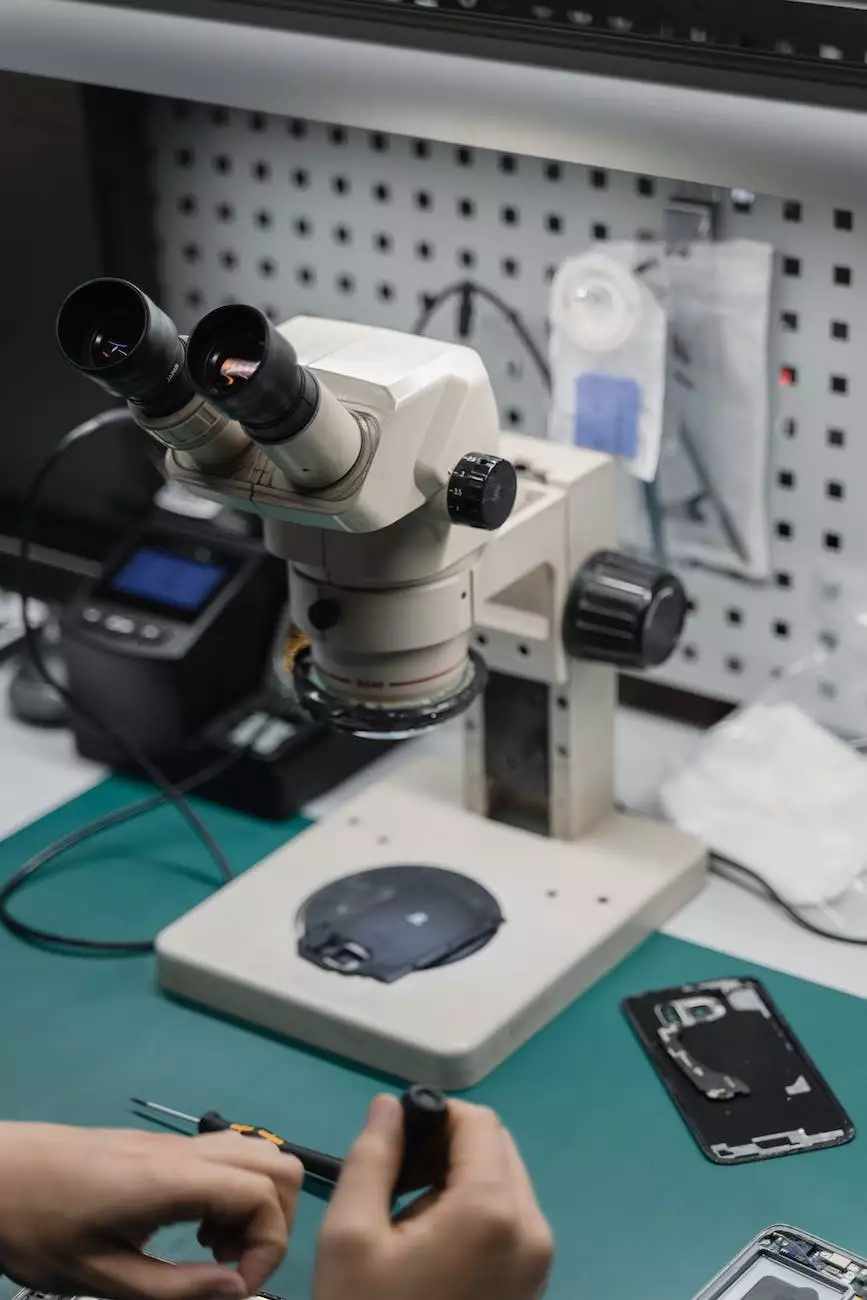

Equipment and Tools:

The quality and suitability of the soldering equipment and tools used also impact soldering time. Advanced soldering stations, temperature-controlled irons, and the availability of accessories like soldering aids or magnifying tools can streamline the soldering process.

Estimating Soldering Time

While it is challenging to provide an exact timeframe for soldering various components, we can give you a general idea based on our expertise and experience. Keep in mind that these are approximate estimates and the actual time required may vary.

Basic Components:

For simple through-hole soldering of basic components like resistors or capacitors, it may usually take around 2-5 seconds per joint.

Integrated Circuits (ICs):

Soldering ICs can be more time-consuming due to their higher pin count and complex layout. The average time for soldering ICs ranges from 5-15 seconds per joint.

Fine-Pitch SMD Components:

Soldering fine-pitch surface mount components demands greater precision and often requires additional time. The average time for soldering such components can range from 10-30 seconds per joint.

Complex Circuitry:

In cases where intricate circuit boards or complex circuitry are involved, the time required may increase significantly. It can take anywhere from 30 seconds to a few minutes per joint, depending on the complexity.

Conclusion

In conclusion, the time it takes to make a solder joint depends on various factors, including surface preparation, component complexity, soldering techniques, soldering skill, and equipment used. By understanding these factors and estimating the appropriate time for soldering different components, you can optimize your soldering process and ensure high-quality results.

At our SEO services, we strive to provide you with comprehensive information and assistance to help you outrank other websites. For all your soldering needs and reliable SEO services, contact us today.