IPC-A-600 or IPC-6012 – Which Standard is Right for Me

Are you seeking to understand the differences between IPC-A-600 and IPC-6012 and determine which standard is the most suitable for your business in the field of Business and Consumer Services - SEO services? Look no further! In this guide, we will provide you with comprehensive information and detailed comparisons to help you make the right decision.

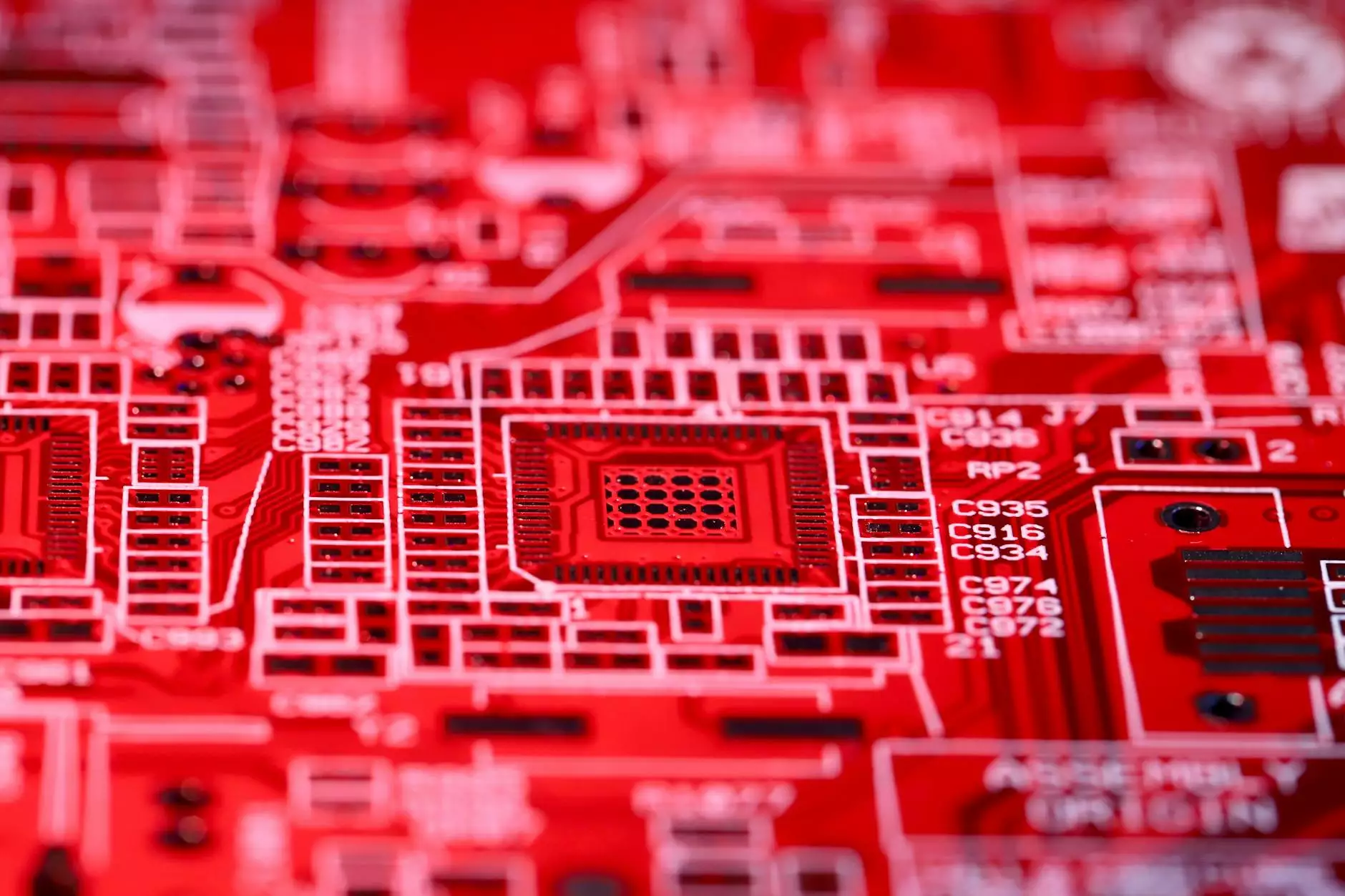

Understanding IPC-A-600 Standard

The IPC-A-600 is a widely recognized standard developed by the Association Connecting Electronics Industries (IPC) for printed circuit board (PCB) manufacturers. It outlines the acceptable quality levels for bare PCBs, providing a set of criteria that enable uniform evaluations in terms of visual and dimensional characteristics.

Key Features of IPC-A-600 Standard

- Broadly covers inspection requirements for PCBs

- Sets the standards for dimensional measurements

- Provides guidelines for assessing visual imperfections

- Defines acceptance and rejection criteria

- Ensures consistent quality control

Understanding IPC-6012 Standard

In contrast, the IPC-6012 standard focuses on the performance and qualification requirements for rigid PCBs. It defines the quality and reliability specifications necessary for the assembly and manufacture of rigid PCBs that will ultimately be used in various electronic products.

Key Features of IPC-6012 Standard

- Emphasizes the performance and reliability of rigid PCBs

- Defines material and construction requirements

- Specifies testing procedures and criteria

- Guides manufacturers in achieving consistent quality

Comparing IPC-A-600 and IPC-6012 Standards

While both standards are essential in the PCB industry, it is crucial to understand their differences to determine which one aligns best with your specific business needs. Let's dive into a detailed comparison:

1. Scope and Application

The IPC-A-600 standard primarily focuses on visual and dimensional characteristics, inspecting bare PCBs without addressing the performance requirements. On the other hand, the IPC-6012 standard emphasizes the quality and reliability of rigid PCBs used in electronic products.

2. Quality and Acceptance Criteria

IPC-A-600 sets forth the guidelines to assess visual aspects such as surface finishes, holes, conductive patterns, and solderability. IPC-6012, however, introduces specific material requirements, testing procedures, and acceptance criteria related to the performance and reliability of rigid PCBs.

3. Product Types

IPC-A-600 covers a broader range of products as it addresses the inspection requirements for bare PCBs, while IPC-6012 focuses solely on rigid PCBs used in various electronic applications.

4. Application Industries

While both standards have relevance across multiple industries, understanding your specific industry requirements can help guide your choice. IPC-A-600 finds applications in PCB manufacturing, whereas IPC-6012 is more suitable for businesses involved in electronic product assembly.

Making an Informed Decision

Choosing between IPC-A-600 and IPC-6012 requires a thorough evaluation of your business goals, industry requirements, and project specifications. Consider the following factors:

1. Nature of Your Business

Assess whether your core business operation revolves around PCB manufacturing or electronic product assembly. This will help prioritize the standard that aligns best with your operational focus.

2. Quality and Performance Requirements

Determine the level of quality and performance you need for the PCBs you manufacture or use. Consider factors such as reliability, durability, and specific industry compliance.

3. Industry Standards and Regulations

Research the industry-specific standards and regulations that apply to your products or services. Understanding these requirements will guide you in selecting the appropriate IPC standard.

4. Collaboration with Suppliers and Contractors

If you work closely with PCB manufacturers or electronic product assemblers, consult with them to ensure alignment between your chosen standard and their capabilities and expertise.

Concluding Thoughts

Choosing between IPC-A-600 and IPC-6012 can significantly impact the success and quality of your PCB manufacturing or electronic product assembly business. By understanding the nuances and specific focus of each standard, you can make an informed decision that ultimately enhances customer satisfaction and industry compliance.

At SEO in Sydney, we understand the importance of making the right choices for your business. Contact us today for personalized guidance and top-notch SEO services tailored to your industry and unique requirements.