Are Voids in Solder Joints Really an Issue?

The Importance of Voids in Solder Joints

Voids in solder joints can be a critical concern when it comes to the quality and reliability of electronic components. The presence of voids, or air pockets, within solder joints can lead to a range of issues that affect the performance and lifespan of electronic devices. In this article, we will explore why voids in solder joints are a significant concern and the potential consequences they can have on electronic assemblies.

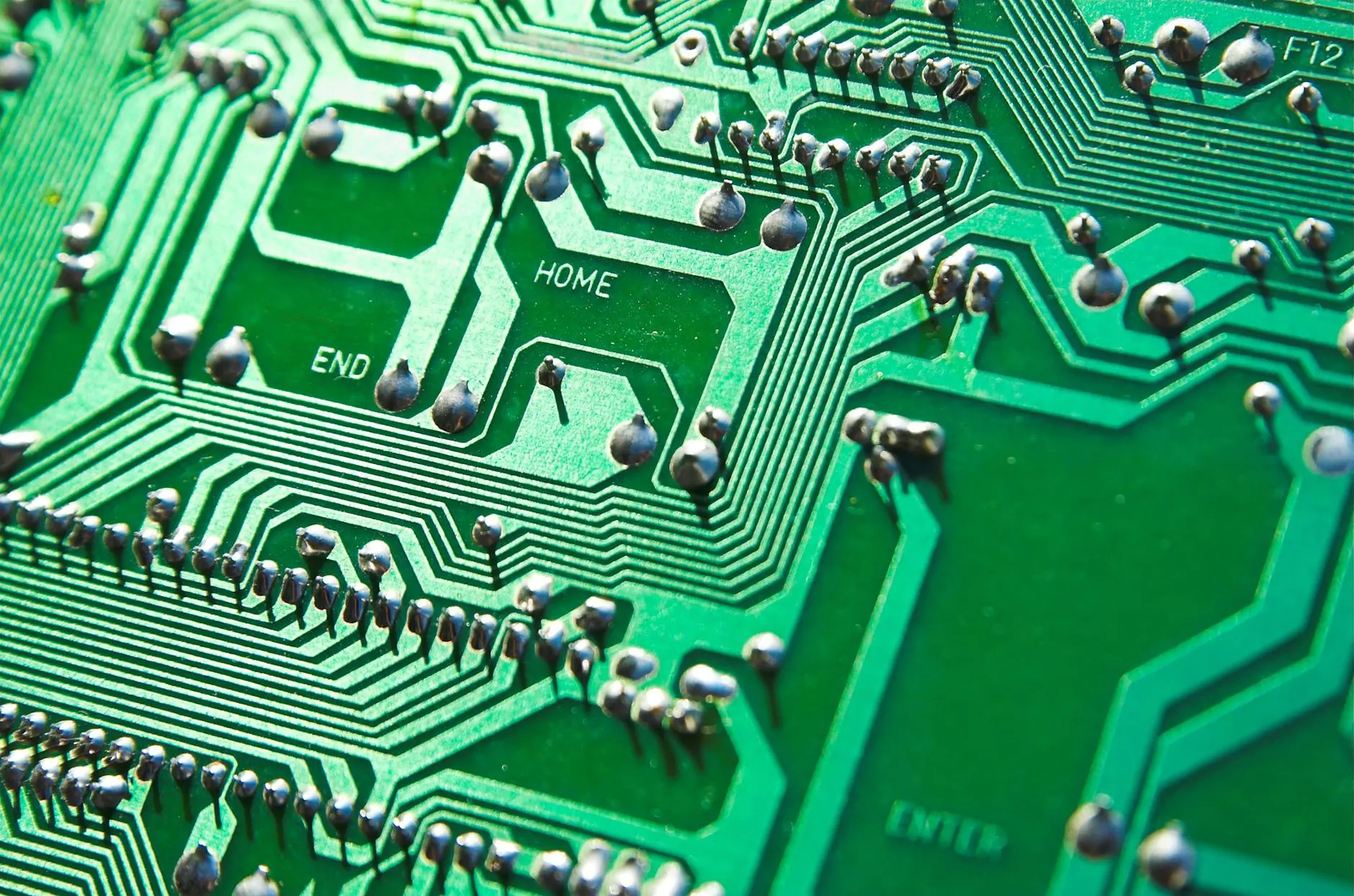

Understanding Solder Joints

Before diving into the possible issues caused by voids, it's essential to understand the basics of solder joints. Solder joints are created by melting solder alloy between two or more metal surfaces to form a bond. This bonding process is commonly used in the assembly of electronic components and printed circuit boards (PCBs).

The Role of Solder Joints in Electronics

Solder joints play a critical role in ensuring the electrical and mechanical integrity of electronic assemblies. They provide electrical conductivity and act as a mechanical connection between components and PCBs. Additionally, solder joints aid in dissipating heat generated by electronic components, preventing overheating and potential damage.

Potential Issues Caused by Voids

Voids in solder joints can introduce a range of problems that compromise the functionality and reliability of electronic devices. Here are some key concerns:

1. Weak Mechanical Strength

Voids weaken the mechanical strength of solder joints, making them more susceptible to mechanical stress, vibrations, and thermal cycles. This can lead to joint failure and ultimately result in malfunctions or complete device failure.

2. Increased Electrical Resistance

The existence of voids in solder joints can increase the electrical resistance of the connection, affecting the flow of current. Higher electrical resistance can lead to voltage fluctuations, reduced signal quality, and even circuit failure.

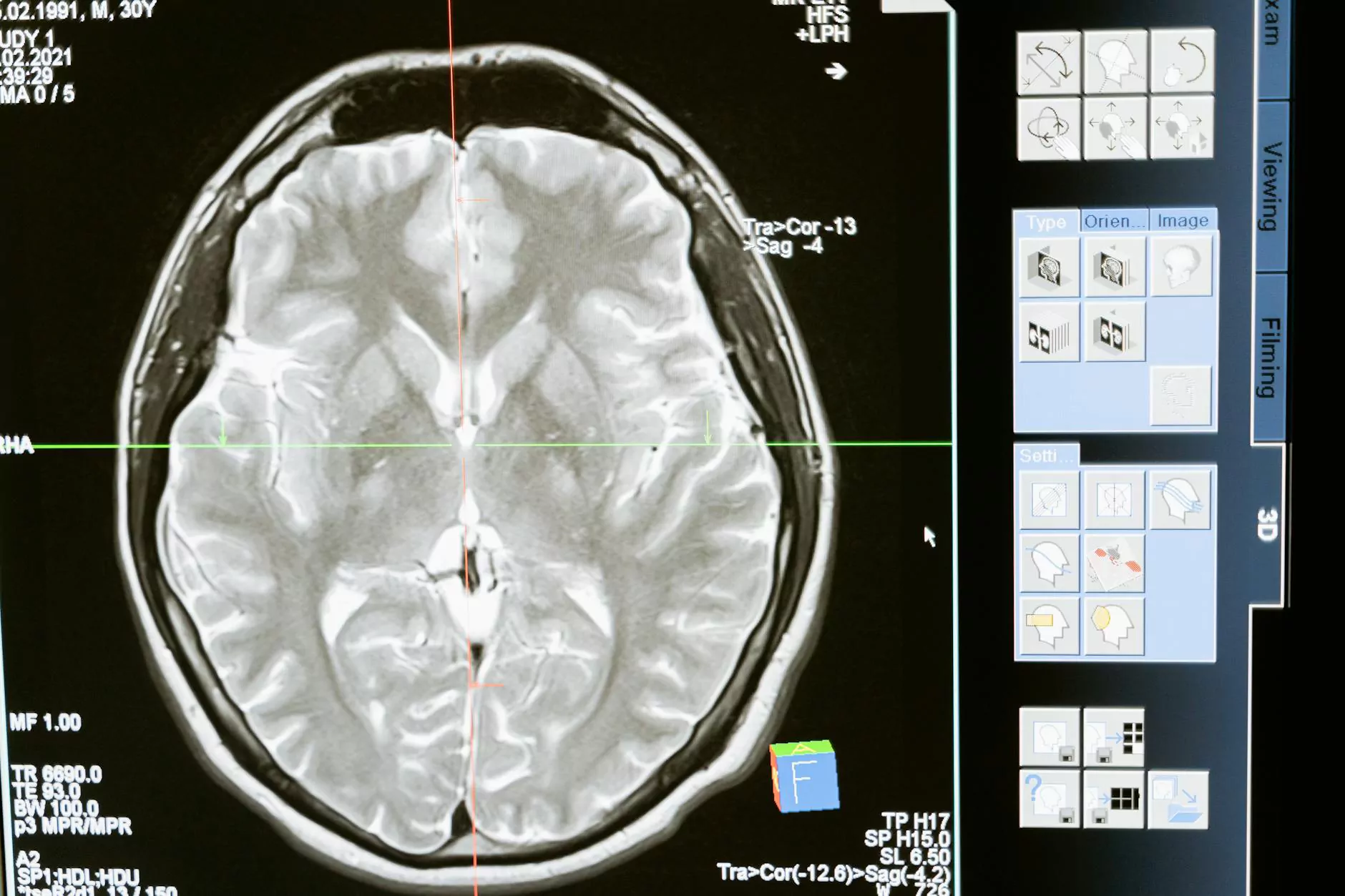

3. Thermal Issues

Voids disrupt the heat dissipation capabilities of solder joints, causing localized heating and thermal stress. This can create hot spots, leading to overheating of components and potential thermal damage.

4. Poor Solder Wetting

Voids result in poor wetting of the solder, reducing the surface area of the joint where a solid bond is formed. Inadequate wetting can lead to incomplete soldering, poor electrical connectivity, and lower overall solder joint reliability.

5. Environmental Impact

Voids can also make solder joints more susceptible to environmental factors such as moisture, dust, and contaminants. This can accelerate corrosion and degradation of the joint, further compromising its performance and longevity.

Preventing and Managing Voids

Although it may be challenging to eliminate voids entirely, steps can be taken to minimize their occurrence and mitigate their impact:

1. Optimal Soldering Conditions

Using appropriate soldering techniques, such as controlling the temperature, dwell time, and solder alloy composition, can greatly reduce the likelihood of void formation.

2. Design Considerations

Implementing proper pad layout, component placement, and solder mask design can optimize the soldering process and minimize the chances of voids.

3. Inspection and Quality Control

Rigorous inspection methods, including X-ray inspection and automated optical inspection (AOI), help detect and quantify the presence and extent of voids. Implementing quality control measures ensures that only reliable soldered joints make it through the manufacturing process.

Choose SEO in Sydney for Professional SEO Services

When it comes to optimizing your website and driving organic traffic, expertise matters. SEO in Sydney offers top-notch SEO services tailored to meet your business's unique needs. Our team of experienced professionals understands the intricacies of SEO, content optimization, and keyword research.

Whether you are looking to improve your website's visibility, increase organic rankings, or enhance your overall digital marketing strategy, SEO in Sydney has the expertise and track record to deliver exceptional results. Contact us today to take your online presence to the next level!