IPC-A-610 Acceptable Requirements for Nicks and Chip-Outs

Introduction

Welcome to SEO in Sydney, your trusted partner for comprehensive SEO services in the Business and Consumer Services industry. In this article, we will delve into the essential topic of IPC-A-610 acceptable requirements for nicks and chip-outs, providing you with the necessary knowledge to maintain high-quality standards in your operations.

Understanding IPC-A-610

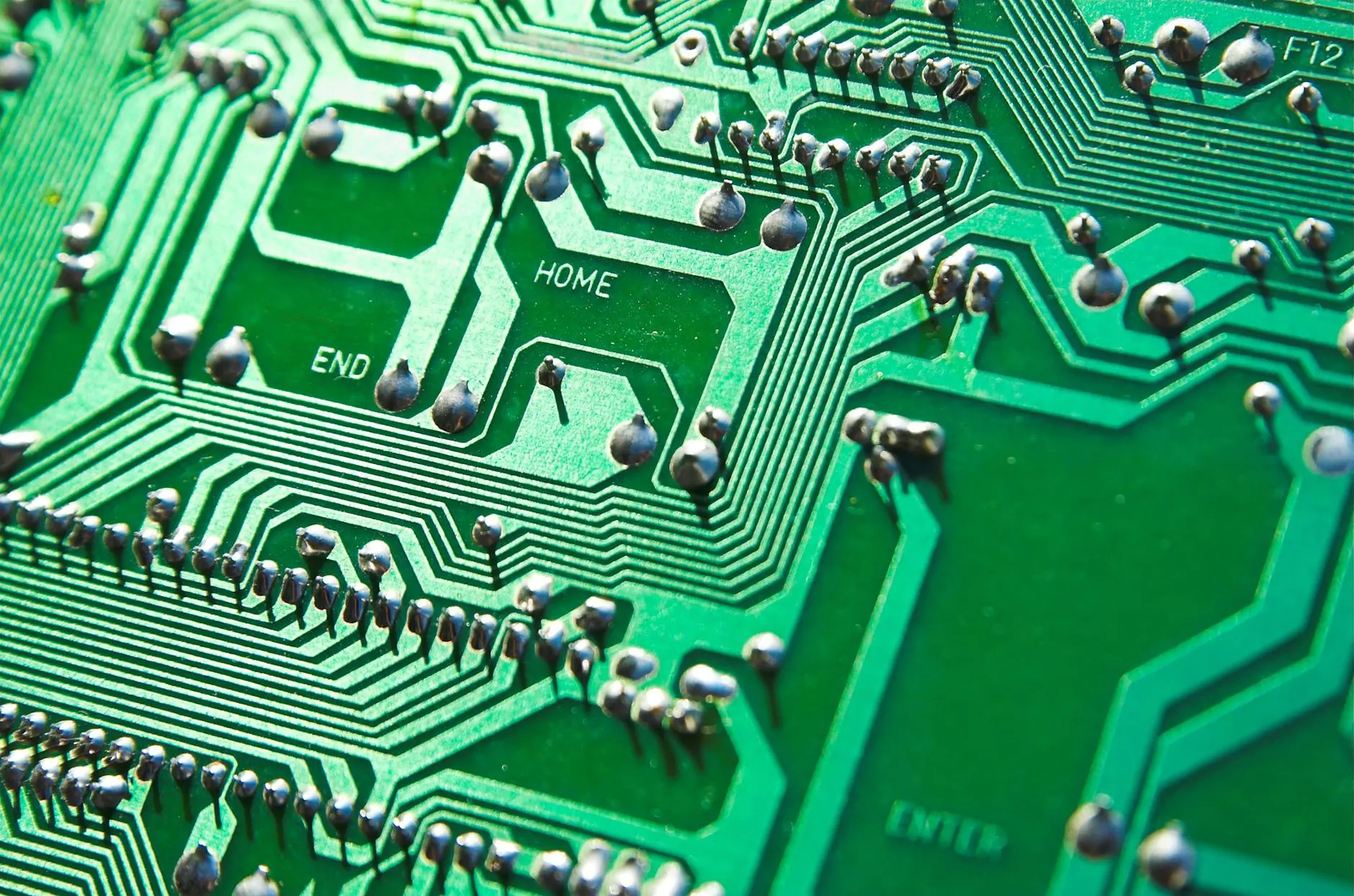

IPC-A-610, or Acceptability of Electronic Assemblies, is an internationally recognized standard developed by the IPC (Association Connecting Electronics Industries). It provides guidelines for evaluating the acceptability of electronic assemblies based on visual inspection criteria.

What are Nicks?

Nicks refer to small indentations or cuts on the surface of electronic components. They can occur during the manufacturing, handling, or installation processes. It is crucial to understand and adhere to acceptable nick requirements to ensure optimal product performance and reliability.

Understanding Chip-Outs

Chip-outs, on the other hand, are complete or partial removal of material from an electronic component or PCB (Printed Circuit Board). These can result from various factors, including machining errors, improper handling, or component defects. Proper evaluation and adherence to acceptable chip-out requirements are vital to maintain the integrity of the assembly.

IPC-A-610 Acceptable Requirements

The IPC-A-610 standard provides clear and comprehensive guidelines for determining acceptable requirements for nicks and chip-outs. It takes into account factors such as location, depth, and impact on electrical functionality. These requirements help manufacturers, assemblers, and inspectors evaluate whether a nick or chip-out falls within acceptable limits or needs to be repaired or replaced.

Factors Considered in Evaluation

During the evaluation process, the following factors are considered to determine acceptability:

- Location: The location of the nick or chip-out is crucial in determining its acceptability. Certain areas of the assembly may be more critical than others, and nicks or chip-outs in those areas may require stricter evaluation.

- Depth: The depth of the nick or chip-out plays a significant role as deeper nicks or chip-outs can compromise the structural integrity and functionality of the assembly.

- Electrical Functionality: Nicks or chip-outs that impact the electrical functionality of the assembly, such as exposed conductive traces or pads, require immediate attention and remediation.

- Component Type: Different components may have varying acceptable requirements for nicks and chip-outs. Consideration is given to the component type and its criticality to the overall assembly performance.

Importance of Adhering to Acceptable Requirements

Ensuring compliance with IPC-A-610 acceptable requirements for nicks and chip-outs is of utmost importance for several reasons:

- Reliability: Adhering to the acceptable requirements helps ensure the reliability and longevity of the electronic assembly by preventing premature failures caused by nicks or chip-outs.

- Quality Assurance: Following the IPC-A-610 standard demonstrates a commitment to high-quality standards, enhancing customer trust and satisfaction.

- Compliance: Many industries and sectors require adherence to IPC standards for electronic assemblies. Compliance with acceptable nick and chip-out requirements helps meet these industry-specific regulations.

- Cost Efficiency: By identifying and rectifying nicks or chip-outs during inspection, costly rework or product failures can be minimized, leading to improved cost efficiency.

Conclusion

Understanding and implementing the IPC-A-610 acceptable requirements for nicks and chip-outs is essential for maintaining high-quality standards and ensuring the reliability of electronic assemblies. At SEO in Sydney, we provide top-notch SEO services to businesses in the Business and Consumer Services industry, assisting them in enhancing their online presence and reaching their target audience effectively. Contact us today to learn more about our services!