Understanding Bare Board Inspection: An Essential Quality Control Measure

Welcome to the comprehensive guide on bare board inspection - an essential quality control measure in the electronics industry. In this article, we will delve into the significance of bare board inspection, its role in ensuring reliable and defect-free printed circuit boards (PCBs), and how professional SEO services can enhance your online visibility to outperform competitors in the market.

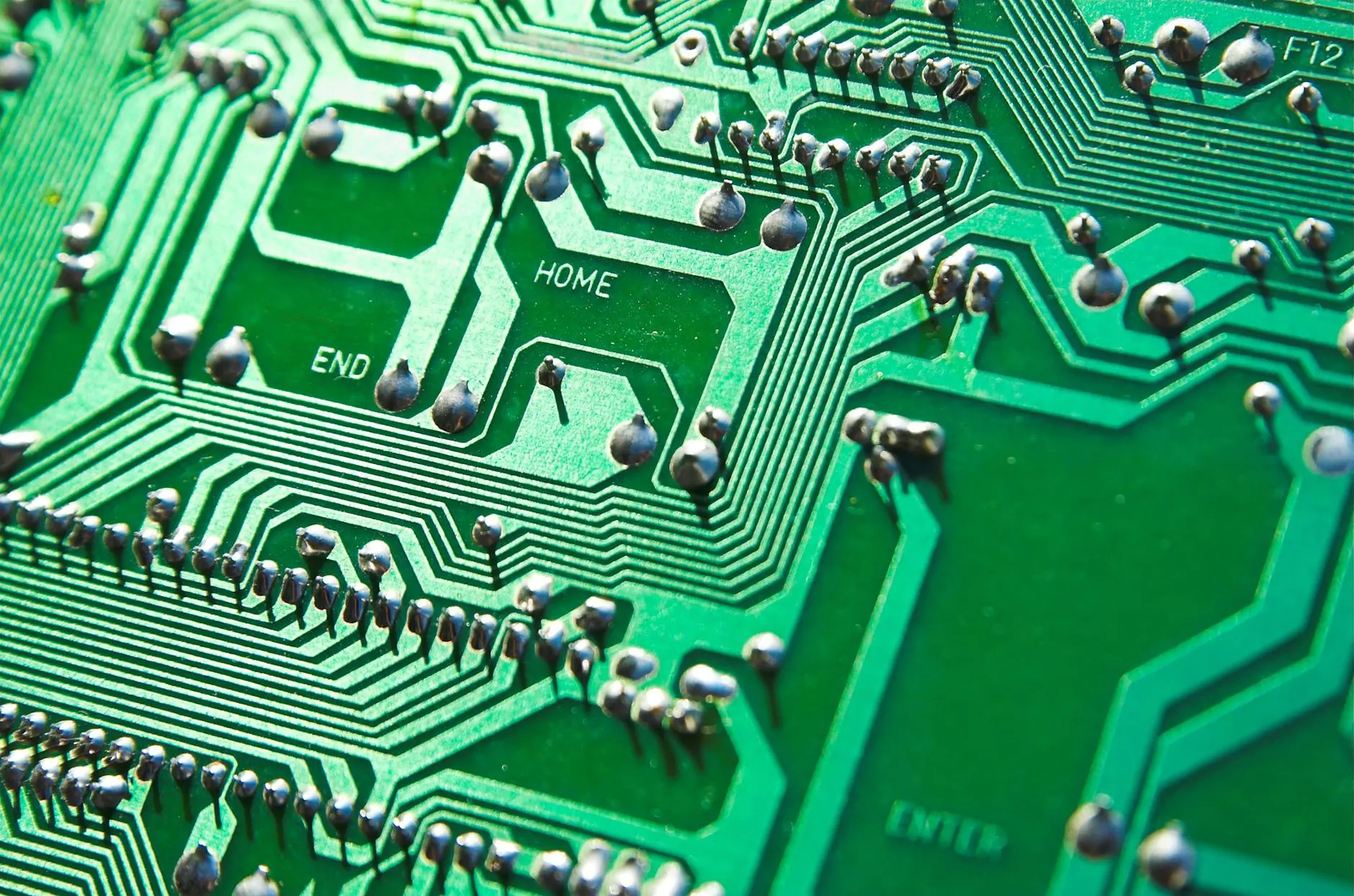

The Importance of Bare Board Inspection

Bare board inspection is a critical step in the manufacturing process of printed circuit boards. It involves thorough examination and testing of the board's physical and electrical attributes before the components are soldered onto them. By conducting this inspection, electronic manufacturers can identify and rectify any potential defects or issues that may compromise the functionality of the final product.

Several elements are typically assessed during bare board inspection, including:

- Conductor Width and Spacing: Ensuring that the conductive traces on the board are properly spaced and have the correct width, minimizing the chances of short circuits or performance issues.

- Solder Mask Alignment: Verifying the alignment and coverage of the solder mask, which protects the conductive traces from oxidation and accidental contact.

- Pad Size and Shape: Checking the integrity and correctness of the pads, ensuring proper electrical connection and secure component mounting.

- Hole Size and Position: Accurate assessment of the holes' dimensions and positions, critical for component insertion, proper soldering, and overall board functionality.

- Silkscreen Legibility: Verifying the readability of any text, symbols, or markings present on the board, ensuring clear identification and assembly instructions for the components.

Ensuring Reliable and Defect-Free PCBs

Bare board inspection plays a pivotal role in ensuring the production of reliable and defect-free printed circuit boards. By identifying and rectifying potential issues at an early stage, manufacturers can significantly decrease the chances of costly recalls, performance failures, or customer dissatisfaction.

Optimal bare board inspection relies on employing cutting-edge technologies and comprehensive quality control measures. Advanced inspection techniques such as automated optical inspection (AOI) and automated X-ray inspection (AXI) enable efficient analysis of various aspects of the board, enhancing accuracy and reliability.

Enhancing Your Online Visibility with Professional SEO Services

In the competitive landscape of the electronics industry, it is crucial to establish a strong online presence that efficiently showcases your bare board inspection services. Professional SEO services specialize in optimizing your website's visibility by strategically implementing relevant keywords, generating high-quality backlinks, and improving overall user experience.

By prioritizing SEO efforts, your website can secure higher search engine rankings, outranking competitors and capturing greater organic traffic. Building optimized landing pages, creating engaging blog content, and leveraging social media platforms are just a few of the tactics employed by SEO experts to strengthen your online brand presence.

Conclusion

Bare board inspection stands as a paramount quality control measure in the electronics industry, ensuring reliable and defect-free printed circuit boards. By understanding the significance of this inspection process, electronic manufacturers can deliver superior products to their customers, enhancing brand reputation and customer satisfaction. Partnering with professional SEO services further fortifies your online presence, enabling you to outrank competitors and augment business growth. Embrace the power of bare board inspection and SEO to unlock your business's true potential in the ever-evolving electronics market.