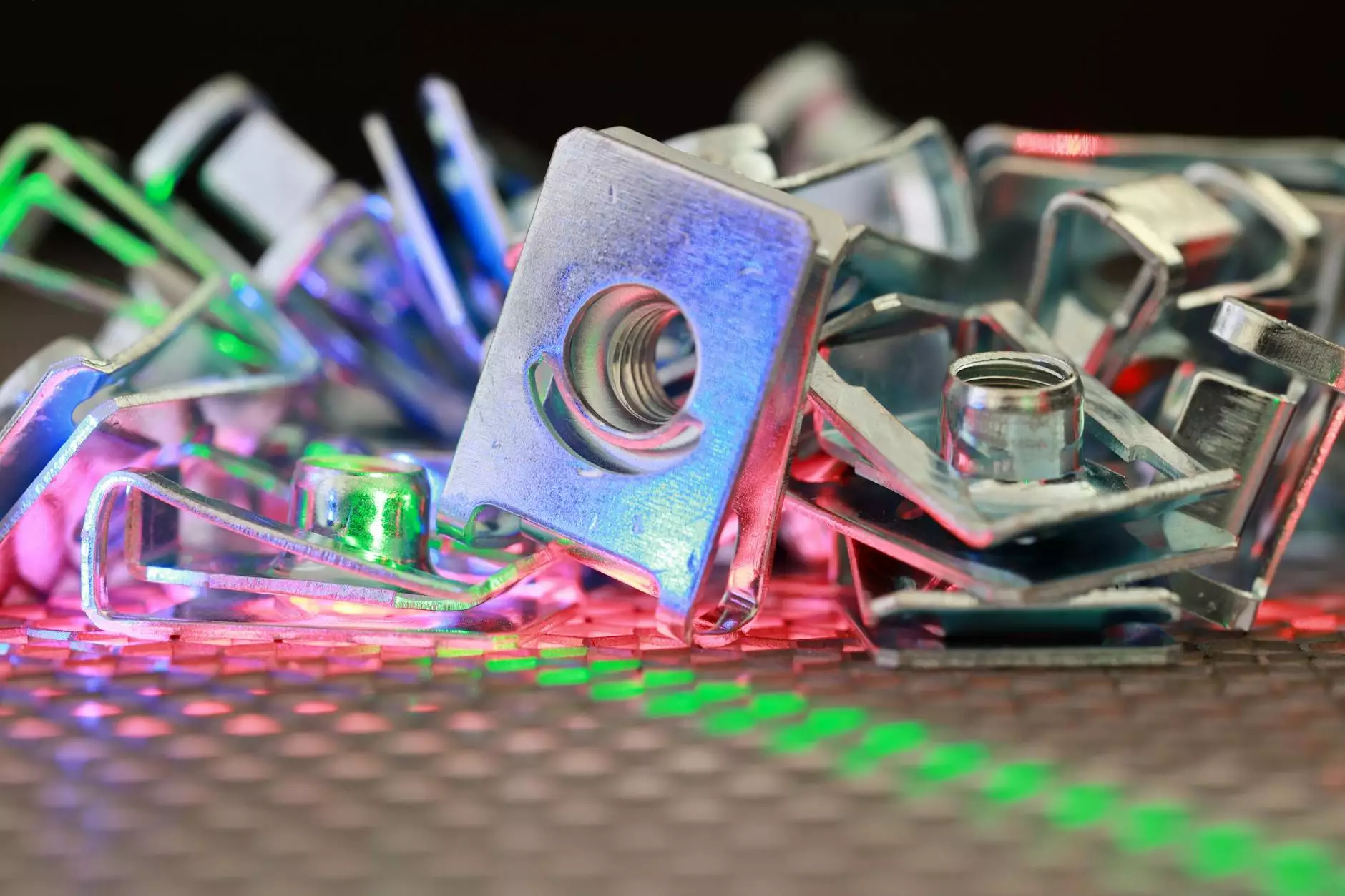

Welcome to the Premier Titanium Bolts Factory

Titanium bolts are a crucial component in various industries, providing strength, durability, and resistance to corrosion that few other materials can match. At our titanium bolts factory, we pride ourselves on producing top-quality titanium fasteners tailored to meet the specific needs of our clients. In this comprehensive article, we will explore the benefits of titanium, the manufacturing processes involved, and the applications that showcase the superiority of our products. Let's dive in!

Understanding Titanium: The Ultimate Material

Titanium is a remarkable metal, characterized by its lightweight, yet incredibly strong properties. Here are some reasons why titanium stands out in the world of materials:

- Strength-to-Weight Ratio: Titanium is significantly stronger than steel, while being much lighter, making it an ideal choice for a variety of applications.

- Corrosion Resistance: This metal naturally forms a protective oxide layer, giving it extraordinary resistance to corrosion in harsh environments.

- Biocompatibility: Titanium is non-toxic and highly biocompatible, making it suitable for medical applications, including implants.

- High Temperatures: Titanium maintains its strength and stability at elevated temperatures, suitable for aerospace and industrial applications.

Why Choose Our Titanium Bolts Factory?

At titaniumbolts.com, we set ourselves apart as a leading titanium bolts factory through our commitment to quality and innovation. Here are some reasons why our products are preferred:

- State-of-the-Art Manufacturing: We utilize advanced technology and equipment in our manufacturing processes, ensuring precision and consistency in every bolt.

- Custom Solutions: We offer customization options to meet specific project requirements, including diameters, lengths, and grades of titanium.

- Quality Assurance: Every batch of titanium fasteners goes through rigorous quality checks to ensure they meet the highest standards.

- Experienced Team: Our team of experts brings years of experience and knowledge to the industry, ensuring that we remain at the forefront of innovations in titanium manufacturing.

The Manufacturing Process: How We Create Superior Titanium Bolts

The journey of crafting high-quality titanium bolts begins with sourcing the finest titanium alloys. The following outlines the meticulous manufacturing process undertaken at our titanium bolts factory:

1. Material Selection

We prioritize the selection of high-grade titanium alloys, primarily Ti-6Al-4V, which is well-established for its superior mechanical properties. This alloy comprises 90% titanium, 6% aluminum, and 4% vanadium, making it the go-to choice for many industries.

2. Melting and Forming

The selected titanium alloy is subjected to a melting process using an electric arc furnace. Once melted, it is cast into ingots. These ingots are then hot forged into bars, which serve as the raw material for our titanium bolts.

3. Machining

Using CNC (Computer Numerical Control) machines, we precisely machine the forged bars into bolts. This process ensures high dimensional accuracy, allowing us to manufacture titanium bolts that meet exact specifications.

4. Heat Treatment

To enhance the mechanical properties of the bolts, we perform heat treatment processes. This step increases hardness and strength, tailoring the product to its intended application.

5. Surface Treatment

Our titanium bolts undergo various surface treatments, such as anodizing and passivation, which enhance the corrosion resistance and aesthetic appeal of the product.

6. Quality Control

Finally, each batch of bolts is subjected to stringent quality control tests, including tensile testing, dimensional checks, and surface inspection, ensuring that only the highest quality products leave our factory.

Applications of Titanium Bolts

Titanium bolts are widely used across various industries due to their excellent properties. Here are some notable applications:

Aerospace Industry

The aerospace sector demands lightweight yet durable materials. Titanium bolts are used in aircraft structures, engines, and landing gear, contributing to overall weight reduction without compromising strength.

Medical Equipment

In the medical field, titanium is synonymous with safety and biocompatibility. Our titanium bolts are utilized in surgical implants, dental prosthetics, and orthopedic devices, offering patients reliable and long-lasting solutions.

Automotive Sector

Performance vehicles often incorporate titanium bolts for engine components and exhaust systems. The reduction in weight translates to enhanced speed and fuel efficiency.

Marine and Chemical Industries

Corrosive environments, such as marine applications, benefit significantly from titanium's resistance to rust and degradation, making our bolts a preferred choice for shipbuilding and chemical processing equipment.

Benefits of Working with Us

Partnering with our titanium bolts factory comes with a myriad of benefits:

- Competitive Pricing: We offer great pricing strategies without compromising quality, ensuring our clients receive excellent value.

- Fast Turnaround Times: Our efficient manufacturing process allows us to meet tight deadlines and deliver products on time.

- Excellent Customer Service: We prioritize customer satisfaction and are dedicated to providing support throughout the project lifecycle.

- Innovative Solutions: Our commitment to continuous innovation enables us to develop new products and processes that meet the evolving needs of our customers.

Frequently Asked Questions (FAQs)

Q: What grades of titanium do you offer for bolts?

A: We offer various grades, with Ti-6Al-4V being the most common due to its balance of strength and weight. We can also supply other grades upon request.

Q: Can you provide custom sizes for titanium bolts?

A: Yes, we specialize in custom solutions and can manufacture bolts in a range of sizes to meet specific requirements.

Q: How do I place an order for titanium bolts?

A: You can easily place an order by contacting our sales team through our website or by phone. We’ll guide you through the process and assist with any specifications you need.

Q: What are the lead times for orders?

A: Lead times vary depending on the order size and complexity, but we strive to maintain fast turnaround times and can provide estimates upon order inquiry.

Why Titaniumbolts.com is Your Best Choice

As a reputable titanium bolts factory, titaniumbolts.com stands ready to meet all your titanium fastener needs. Our commitment to excellence, combined with our advanced manufacturing techniques and a top-notch customer service team, makes us a leading choice in the industry. Whether you require standard products or custom solutions, we are here to help you succeed in your projects.

Conclusion

In conclusion, titanium bolts are an essential component in numerous applications across various industries. With their unbeatable strength-to-weight ratio, exceptional resistance to corrosion, and high-temperature stability, they are a reliable choice for critical projects. At our titanium bolts factory, we are proud to supply high-quality titanium fasteners that meet the rigorous standards of our valued clients. Contact us today to learn more about our products and how we can help you achieve your goals with our titanium solutions.