PEM® Nut Soldering Criteria - Train. Work Smarter. Succeed

Introduction

Welcome to our comprehensive guide on PEM® Nut Soldering Criteria. In this article, we will provide you with valuable information and expert tips to enhance your productivity and ensure successful soldering. Whether you are new to soldering or an experienced professional, this guide will equip you with the necessary knowledge to excel in your work.

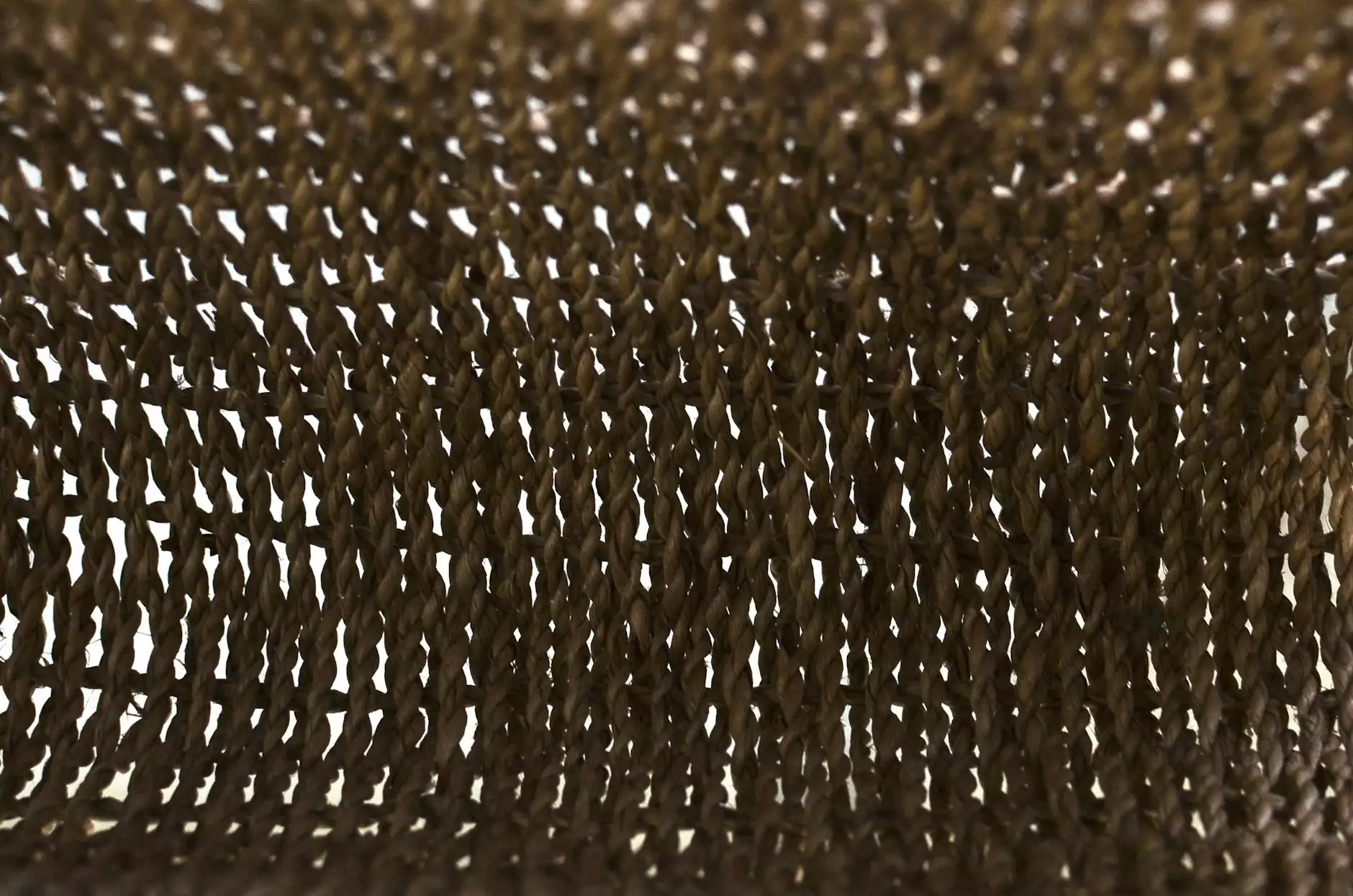

Understanding PEM® Nuts

Before we delve into the soldering criteria, let's start by understanding what PEM® nuts are. PEM® nuts, also known as self-clinching nuts, are fasteners designed to provide strong and reliable threads in thin metal sheets. They eliminate the need for additional hardware, such as screws or bolts, and offer quick and efficient assembly.

The Importance of Soldering Criteria

Proper soldering is crucial for maintaining the integrity and performance of PEM® nuts. Soldering criteria outline the guidelines and standards for achieving optimal soldering results. By following these criteria, you can ensure adequate joint strength, avoid excessive heat damage, and prevent solder voids or insufficient wetting.

Key Factors for Successful Soldering

Successful soldering of PEM® nuts relies on several key factors. Let's explore these factors in detail:

1. Selection of Soldering Materials

Choosing the right soldering materials is essential for achieving high-quality soldered joints. The selection of solder alloy, flux, and cleaning agents plays a crucial role in the soldering process. It is important to consider factors such as compatibility with the base material, melting point, and reliability of the soldering materials.

2. Surface Preparation

Prior to soldering, proper surface preparation is necessary to ensure strong adhesion and effective wetting. The surfaces to be soldered should be clean, free from contaminants, and properly treated if required. This step significantly contributes to the overall soldering success.

3. Temperature and Heating Profile

Controlling the temperature and heating profile during soldering is critical. Both excessive and insufficient heat can lead to joint integrity issues. It is important to follow the manufacturer's guidelines for temperature settings, preheat times, and dwell times to achieve the desired soldering outcome.

4. Soldering Techniques

Adopting appropriate soldering techniques greatly influences the quality of the soldered joints. Techniques such as wave soldering, reflow soldering, or manual soldering may be employed, depending on the application and production requirements. Understanding and applying the correct technique is vital for achieving consistent and reliable results.

5. Inspection and Quality Control

Regular inspection and quality control measures are essential to identify any potential soldering defects or issues. By implementing thorough inspection processes, such as visual inspection, X-ray inspection, or solder joint pull tests, you can ensure compliance with the soldering criteria and maintain high-quality standards.

6. Training and Certification

Investing in training and certification programs can significantly enhance your soldering skills. By acquiring in-depth knowledge of soldering techniques, best practices, and soldering criteria, you will be better equipped to handle complex soldering tasks and deliver exceptional results.

Conclusion

In conclusion, understanding and adhering to PEM® Nut Soldering Criteria is vital for achieving optimal soldered joint performance. By considering factors such as materials selection, surface preparation, temperature control, soldering techniques, and quality control, you can enhance your productivity and work smarter. Remember, success in soldering is a result of continuous learning, practice, and attention to detail. Train yourself, work smarter, and succeed in your soldering endeavors!

Find Expert Assistance for Your Soldering Needs

If you need further assistance or expert guidance on PEM® Nut Soldering Criteria, our team of professionals at SEOinSydney is here to help. With our expertise in SEO services and business and consumer services, we can provide you with comprehensive solutions tailored to your specific needs. Contact us today to unlock the full potential of your soldering projects!