Will I Damage a Wire-In-Board if it is Bent Too Far

Introduction

Welcome to our informative guide on wire bending practices for circuit boards. In this article, we will address the common question - will I damage a wire-in-board if it is bent too far? As a leading provider of SEO services in the business and consumer services industry, we aim to provide you with the most comprehensive and detailed information to help you understand the risks involved and the best practices to follow when bending wires within circuit boards.

The Importance of Proper Wire Bending

Proper wire bending is crucial to ensure the integrity and functionality of a circuit board. When wires are bent incorrectly or beyond their specified bending limits, they can become susceptible to damage, which can ultimately lead to circuit failure or degraded performance.

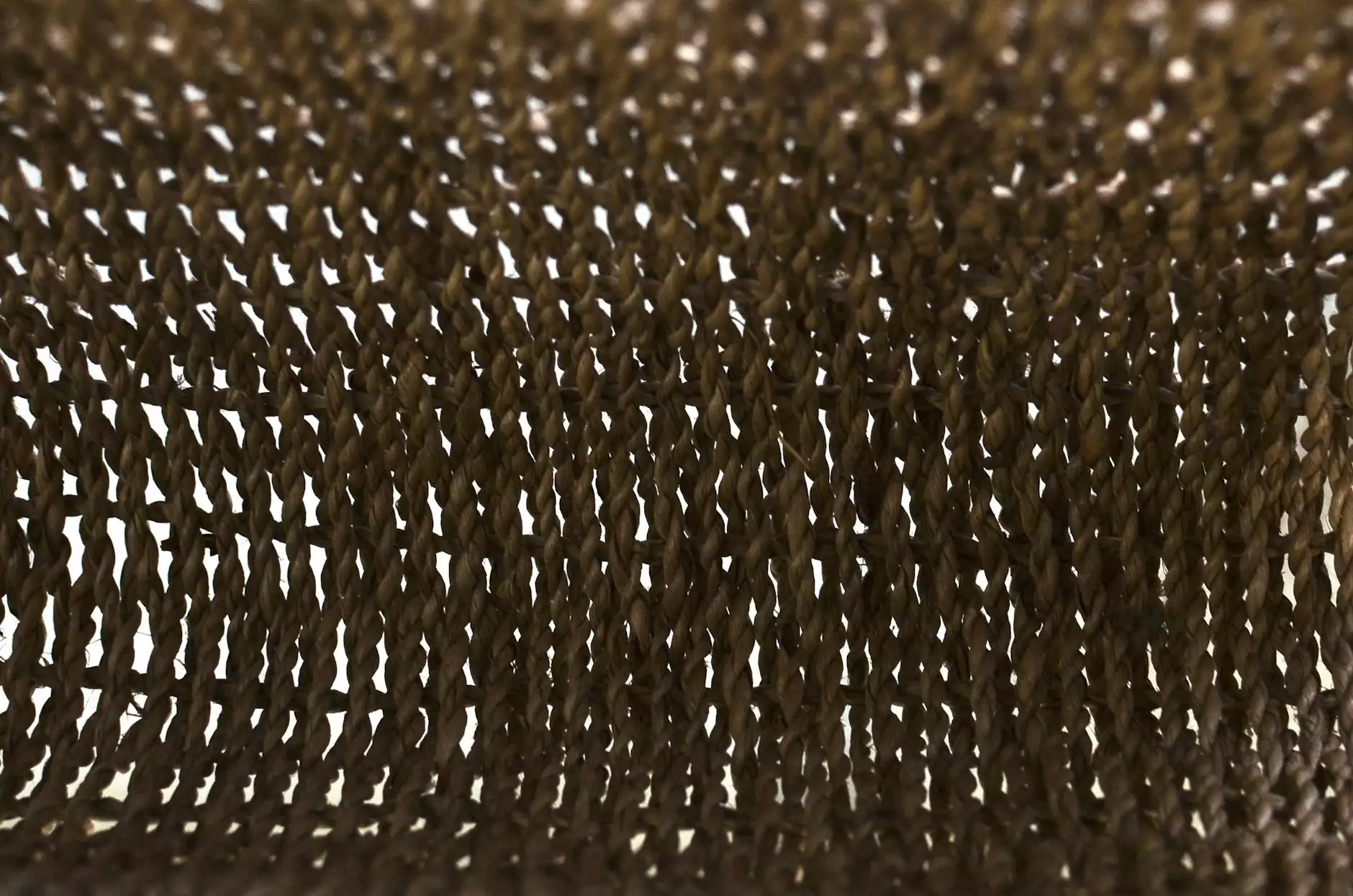

Understanding Wire-In-Board Construction

Before discussing the potential risks associated with bending wires in circuit boards, it is essential to understand the construction of wire-in-board assemblies. A wire-in-board refers to the practice of directly soldering wires onto a printed circuit board (PCB), allowing for the transmission of electrical signals between components.

Potential Risks of Bending Wires Too Far

While wires within circuit boards are designed to withstand a certain degree of bending, exceeding the recommended bending limit can pose several risks:

1. Wire Damage and Fracture

Applying excessive force or bending wires sharply can result in wire damage or fracture. This can lead to electrical discontinuity, affecting the proper functioning of the circuit board.

2. Insulation Damage

Excessive bending can cause the insulation covering the wires to crack or peel, leaving the conductive parts exposed. This can create a potential short circuit or signal interference between adjacent wires or components.

3. Component Stress

Improperly bent wires can place unnecessary stress on neighboring components or solder joints. Over time, this stress can weaken connections, leading to intermittent performance issues or eventual failure.

Best Practices for Wire Bending in Circuit Boards

To prevent potential wire damage and maintain the overall reliability of the circuit board, it is essential to follow these best practices:

1. Refer to Manufacturer Guidelines

Always consult the manufacturer's guidelines and specifications for recommended wire bending limits. These guidelines provide valuable insights into the maximum bending radius and other constraints specific to the wire and board materials.

2. Use Appropriate Tools

Invest in high-quality tools, such as wire-bending jigs, to ensure accurate and controlled bending. These tools provide consistent results and minimize the risk of excessive force applied to the wires.

3. Practice Gentle Bending

Avoid sharp, abrupt bends and instead opt for gentle, gradual bending. This reduces the stress placed on the wires and minimizes the risk of damage or fracture. Take care not to exceed the recommended bending radius provided by the manufacturer.

4. Inspect for Damages

Regularly inspect the wires for any signs of damage, such as cracks, exposed conductive parts, or compromised insulation. Early detection can prevent further issues and prompt necessary repairs or replacements.

In Conclusion

By understanding the risks involved and adopting best practices for wire bending in circuit boards, you can ensure the longevity and functionality of your electronic assemblies. Remember, proper wire bending is a critical aspect of maintaining reliable and high-performing circuit boards.

Reach Out to Our SEO Experts

If you have any further questions or need professional assistance with your search engine optimization (SEO) strategies, feel free to reach out to our team of experts at SEOinSydney. We have a wealth of knowledge and experience in the SEO services industry and are dedicated to helping businesses like yours succeed online.