Webinars - Understanding What Brackets Mean in J-STD-001

Introduction - Exploring the Significance of Brackets in J-STD-001

In this educational webinar, we delve into the intricate world of brackets and their meaning in J-STD-001. These brackets play a crucial role in the electronics manufacturing industry, and understanding their significance is vital for ensuring compliance and maintaining high-quality standards.

Section 1: The Basics of J-STD-001

1.1 Understanding J-STD-001 Requirements

Before we dive deeper into deciphering the meaning of brackets in J-STD-001, let's grasp the fundamental requirements of this industry-standard specification. J-STD-001, published by the IPC (Association Connecting Electronics Industries), outlines the specific criteria for soldered electrical and electronic assemblies.

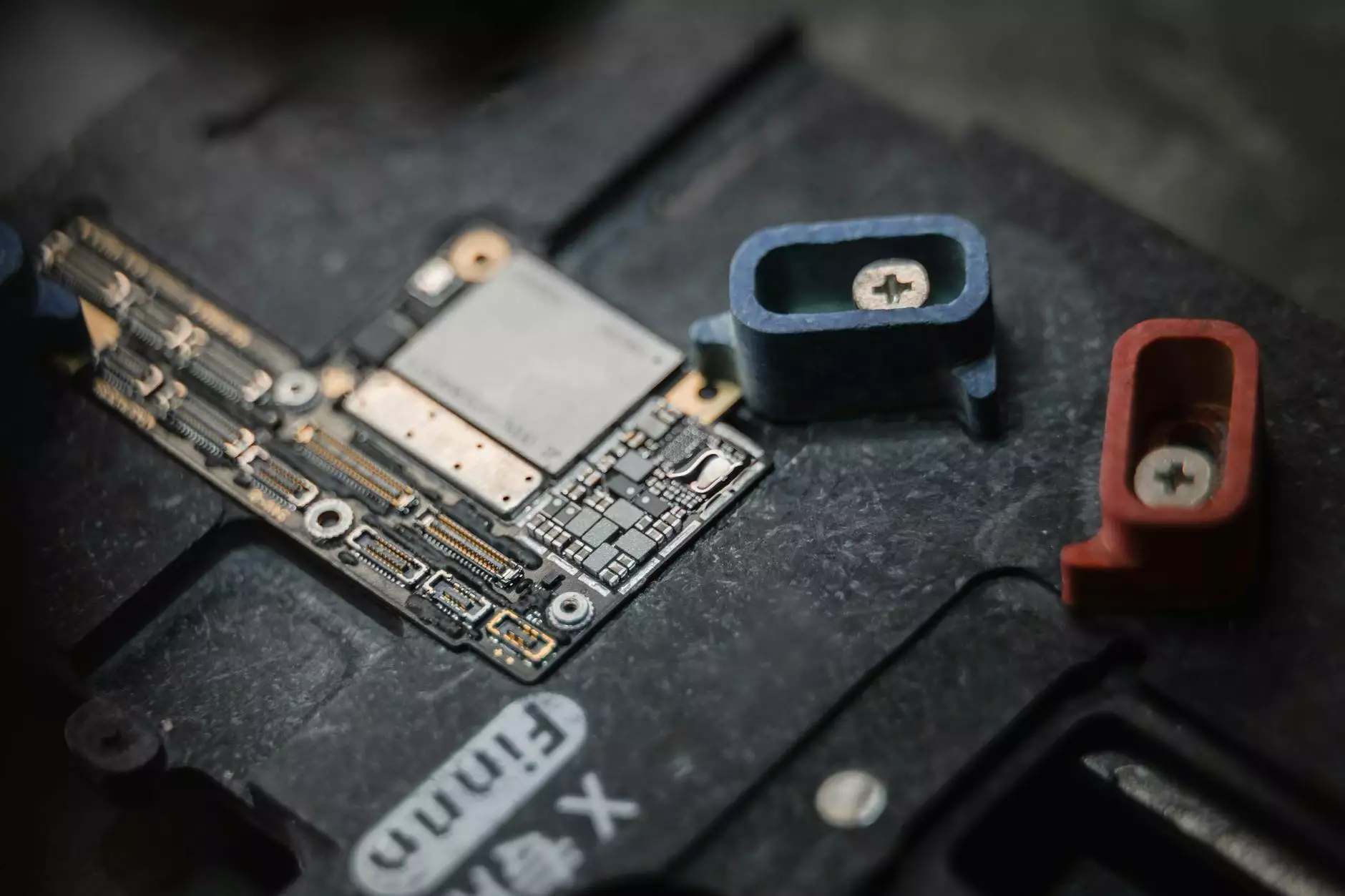

1.2 Overview of Component Mounting Processes

In order to comprehend the importance of brackets in J-STD-001, it's necessary to gain a solid understanding of the various component mounting processes employed in electronics manufacturing. This section will shed light on techniques such as through-hole, surface mount, and mixed technology assembly.

Section 2: Significance of Brackets in J-STD-001

2.1 Brackets as Indicators of Critical Components

Brackets are often used in J-STD-001 to identify critical components within an assembly. These are components that require additional attention during the manufacturing process to ensure their proper functioning and reliability. By recognizing the brackets, manufacturers can prioritize quality control measures and meet the necessary criteria.

2.2 Classifying Brackets and Their Meaning

Understanding the classifications and meanings of brackets is essential for complying with J-STD-001 requirements. We will explore the different types of brackets, such as square brackets, round brackets, and curly brackets, and analyze their significance within the context of this industry standard.

2.3 Interpretation of Brackets in J-STD-001

Interpreting the specific requirements associated with different types of brackets can be complex. This section will provide detailed insights into the interpretation process, offering practical examples and scenario-based explanations to facilitate a thorough understanding.

Section 3: Best Practices for Brackets Usage

3.1 Implementing Brackets in Manufacturing Processes

To ensure adherence to J-STD-001, it is crucial to integrate brackets effectively into the manufacturing processes. This section will discuss the best practices for identifying, marking, and documenting brackets in compliance with industry standards.

3.2 Quality Control Measures for Brackets

Implementing rigorous quality control measures is paramount in the electronics manufacturing industry. This section will focus on the specific quality control measures associated with brackets, including inspection, testing, and verification techniques.

Conclusion - Harnessing the Power of Brackets in J-STD-001

By now, you should have a solid grasp of the significance of brackets in J-STD-001. Through our detailed exploration, we have shed light on their classifications, meanings, and practical implementation strategies. Understanding brackets is essential for compliance and ensuring the highest quality standards in electronics manufacturing.

Join our webinar to dive deeper into the world of brackets in J-STD-001 and equip yourself with invaluable knowledge that will strengthen your expertise in this field. Stay ahead of the curve by understanding what brackets truly mean in the context of this industry standard.

Webinars - Understanding What Brackets Mean in J-STD-001 - Register Now!