Solder Touching Glass Body Components Like Diodes

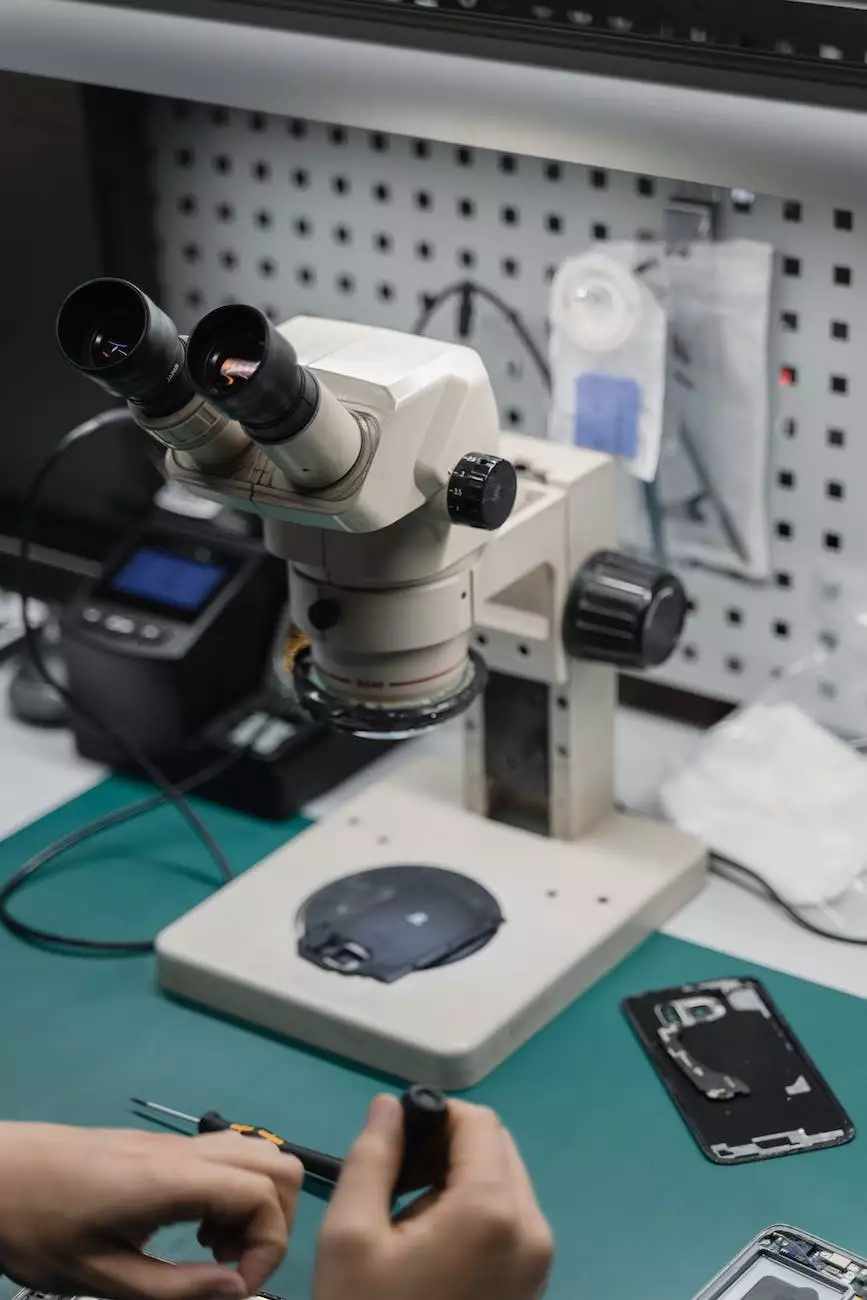

Understanding the Impact of Solder on Glass Body Components

Solder touching glass body components, such as diodes, can have significant implications for the reliability and functionality of electronic devices. When solder comes into contact with glass, it can cause thermal and mechanical stress, potentially leading to cracks, fractures, or even catastrophic failures. As an expert in providing SEO services, we understand the importance of addressing this issue effectively to optimize the performance of your electronic devices.

The Risks of Solder-Glass Interaction

The interaction between solder and glass body components poses various risks that need to be mitigated. These risks include:

- Thermal stress: Solder has different thermal expansion properties than glass, and their mismatch can lead to stress concentration and, ultimately, component failure.

- Mechanical stress: Continuous exposure to mechanical stress, such as during temperature variations or vibrations, can weaken the glass body components.

- Electrical performance degradation: Solder touching the glass body can introduce unwanted electrical connections or short circuits, affecting the overall performance of the device.

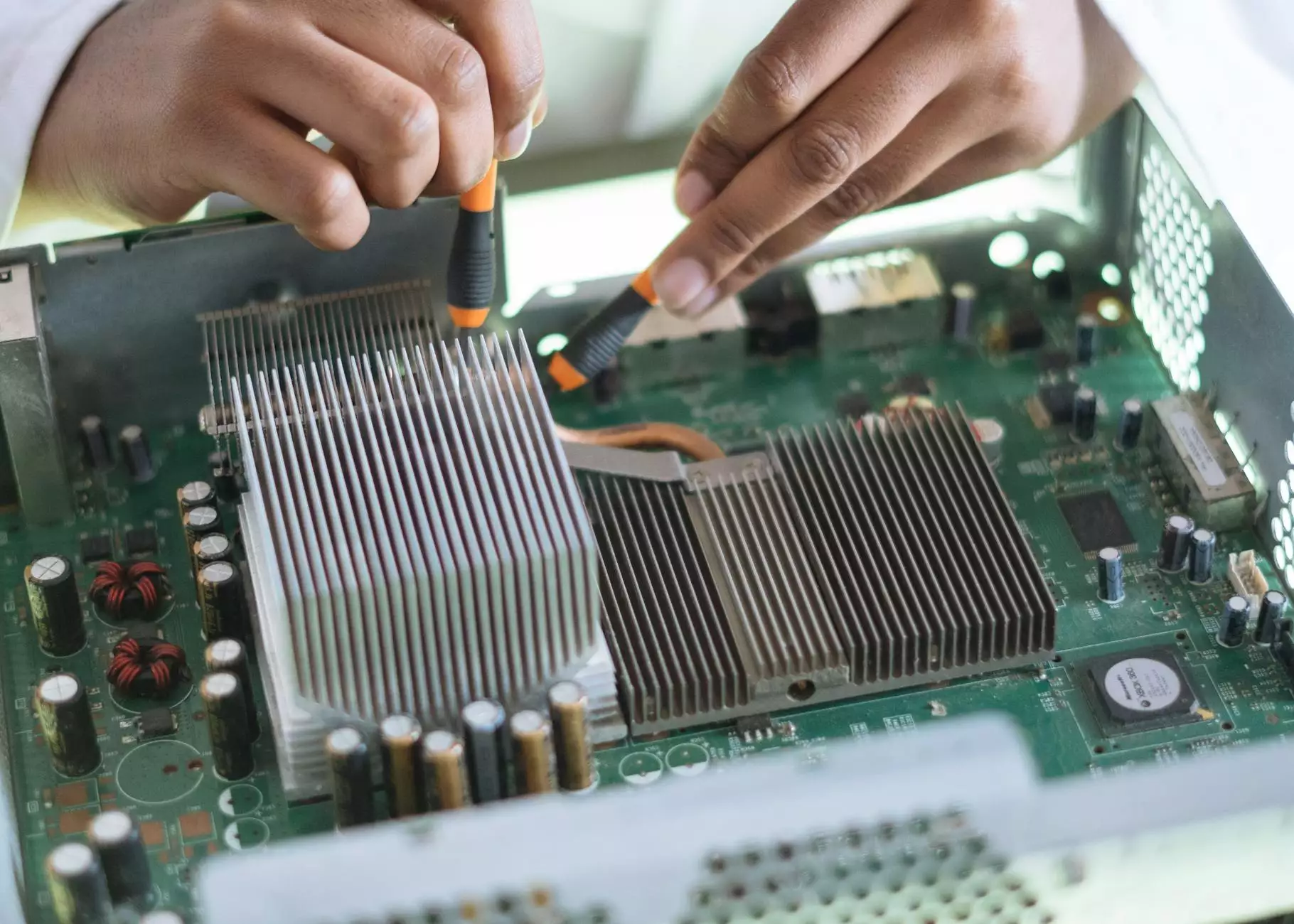

Best Practices to Prevent Solder-Glass Interaction

Prevention is the key to avoiding solder-glass interaction and ensuring the longevity and reliability of your electronic devices. Here are some best practices to consider:

1. Proper Component Selection

Choosing glass body components that are specifically designed to handle soldering processes is crucial. These components are manufactured to withstand the thermal and mechanical stress associated with soldering, reducing the risk of damage.

2. Controlled Heating and Cooling

Implementing controlled heating and cooling techniques during soldering can minimize the thermal stress on the glass body components. Using appropriate soldering equipment and adhering to recommended temperature profiles are essential in this process.

3. Protective Measures

Applying protective coatings or encapsulants to the glass body components can act as a barrier between the solder and the delicate glass surface. These protective measures not only prevent direct contact but also enhance the overall reliability of the device.

4. Proper Handling and Storage

Ensuring proper handling and storage of glass body components before and after soldering is vital. Utilizing anti-static packaging, avoiding excessive force, and protecting the components from moisture or dust will help maintain their integrity.

Partner with Our SEO Services for Expert Guidance

When it comes to optimizing your website's search ranking and outranking competitors, you need a trusted partner in SEO services. At our company, we have a team of experienced professionals who are well-versed in the intricacies of search engine optimization. With our expert guidance, your website can rise above others and secure a prominent position on Google's search results page.

We understand that technical topics like soldering and glass body components may seem complex, but our team excels in delivering comprehensive, detailed information to address your concerns. Remember, our goal is to provide you with the most accurate and up-to-date content, ensuring that your webpage outranks others in the realm of SEO services.

For more information and to learn how we can help you optimize your website for success, feel free to reach out to us. We are dedicated to assisting businesses and consumers like you.