SolderTip #38: Clean vs No-Clean Fluxes

Introduction

Welcome to SEOinSydney.org, your trusted source for high-end SEO services in the business and consumer services industry. In this comprehensive guide, we will delve into the topic of clean vs no-clean fluxes and provide you with all the necessary information to make an informed decision. Whether you are a professional solderer or someone looking to understand the differences, this guide is for you!

What Are Fluxes?

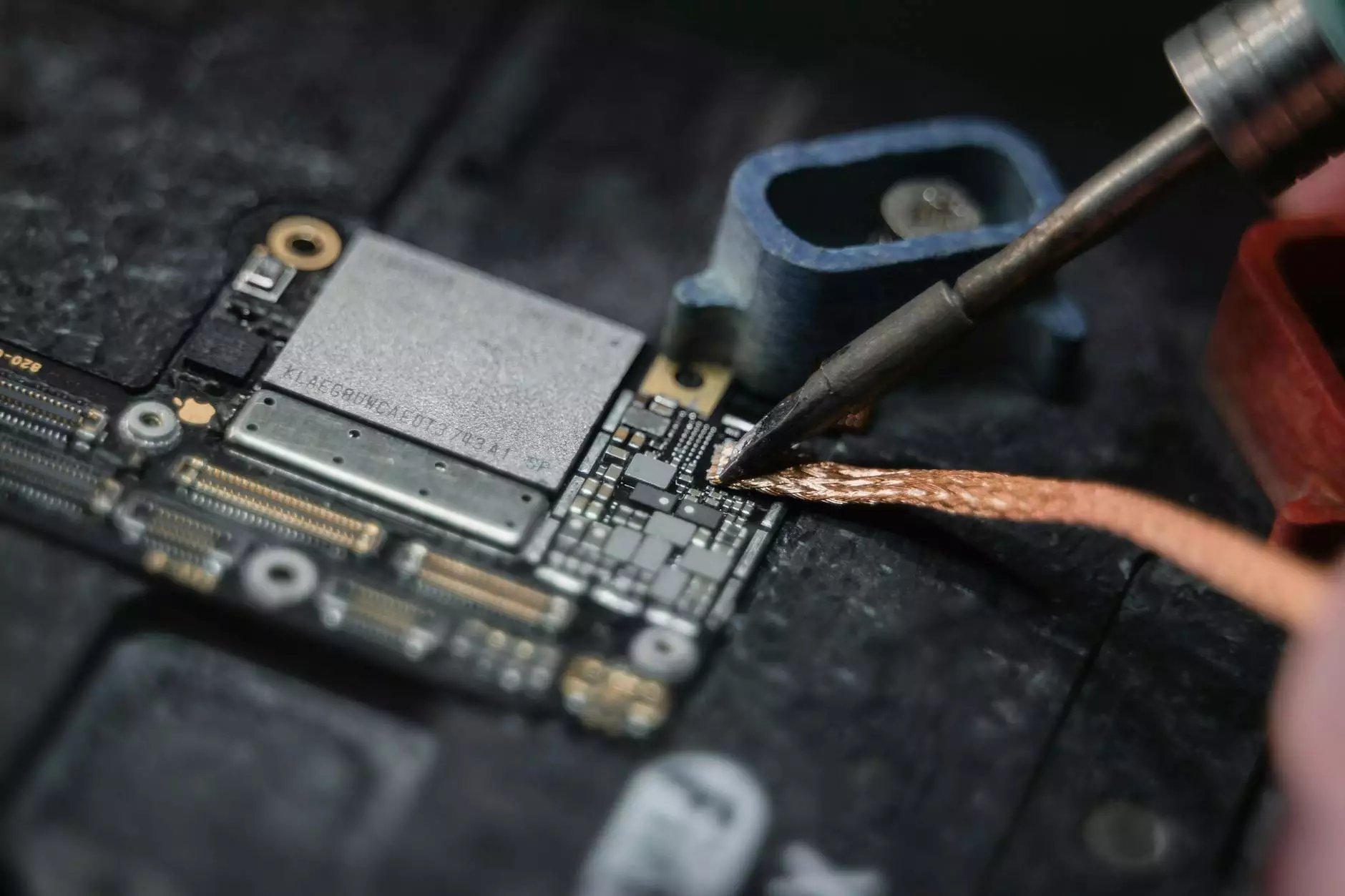

Fluxes play a crucial role in the soldering process. They facilitate the wetting and bonding of solder to the surfaces being joined, allowing for reliable and robust connections. Fluxes also help to remove oxidation and impurities, ensuring a clean and smooth solder joint.

Clean Fluxes

Clean fluxes, as the name suggests, leave behind minimal to no residue after the soldering process. They are typically water-based and are ideal for applications where post-soldering cleaning is required, such as in the electronics industry. Clean fluxes ensure excellent solder joint visibility and effectively prevent electrical shorts and other potential issues.

No-Clean Fluxes

No-clean fluxes, on the other hand, are designed to leave a residual layer after soldering. This layer is non-corrosive and non-conductive, allowing it to be left on the solder joint without requiring any additional cleaning. No-clean fluxes are often used in applications where cleaning may be difficult or impractical, such as for components with fine-pitch leads or sensitive materials.

Key Considerations for Choosing the Right Flux

Application

The first factor to consider is the specific application. Understanding the requirements of your soldering project is crucial in selecting the appropriate flux. Are you working on high-reliability electronics? Do you need to adhere to certain industry standards? Assessing your needs will help you determine whether to go for a clean or no-clean flux.

Post-Soldering Cleaning

If post-soldering cleaning is an essential part of your process or if you are working with sensitive components, clean fluxes might be the better choice. They ensure a residue-free surface, minimizing the risk of potential issues caused by flux residue. On the other hand, if cleaning is a challenge or not required for your specific application, no-clean fluxes may simplify the soldering process and save you time.

Environmental Considerations

Environmental regulations and restrictions may also influence your decision. Clean fluxes are generally more environmentally friendly as they are water-based and produce fewer hazardous by-products. If sustainability and eco-consciousness are important factors for your business, opt for clean fluxes that comply with relevant environmental standards.

Soldering Conditions

The soldering conditions, such as temperature and atmosphere, can impact the performance of fluxes. Different fluxes are formulated for specific temperature ranges, and selecting the appropriate flux ensures optimal soldering results. No-clean fluxes are known to be more stable at higher temperatures, while clean fluxes excel in lower-temperature soldering environments.

Conclusion

Choosing between clean and no-clean fluxes is not a one-size-fits-all decision. It requires careful consideration of various factors, including the application, post-soldering cleaning requirements, environmental impact, and soldering conditions. If you need expert assistance in determining the right flux for your specific needs, rely on SEOinSydney.org for our exceptional SEO services. We specialize in providing tailored solutions to businesses in the business and consumer services industry.

Partner with SEOinSydney.org for Effective SEO Services

When it comes to optimizing your website and outranking your competitors, quality content is just one piece of the puzzle. At SEOinSydney.org, we understand the intricacies of search engine optimization and offer top-notch SEO services to drive organic traffic to your website. Contact us today for a customized SEO strategy that fits your business goals!