3 Strategies for Effective Rework & Repair of PCB's

Introduction

Welcome to our comprehensive guide on effective strategies for reworking and repairing Printed Circuit Boards (PCBs). In this article, we will explore proven techniques that can help you enhance your PCB repair skills. Whether you are a professional technician or a hobbyist, these strategies will provide valuable insights to ensure successful repair and rework of PCBs.

Understanding PCB Rework and Repair

PCB rework and repair involves the process of fixing faults, defects, or damage on printed circuit boards. It is a critical aspect of maintaining the functionality and longevity of electronic devices. Effective rework and repair techniques greatly minimize the need for expensive replacements and ensure optimal performance of electronic equipment.

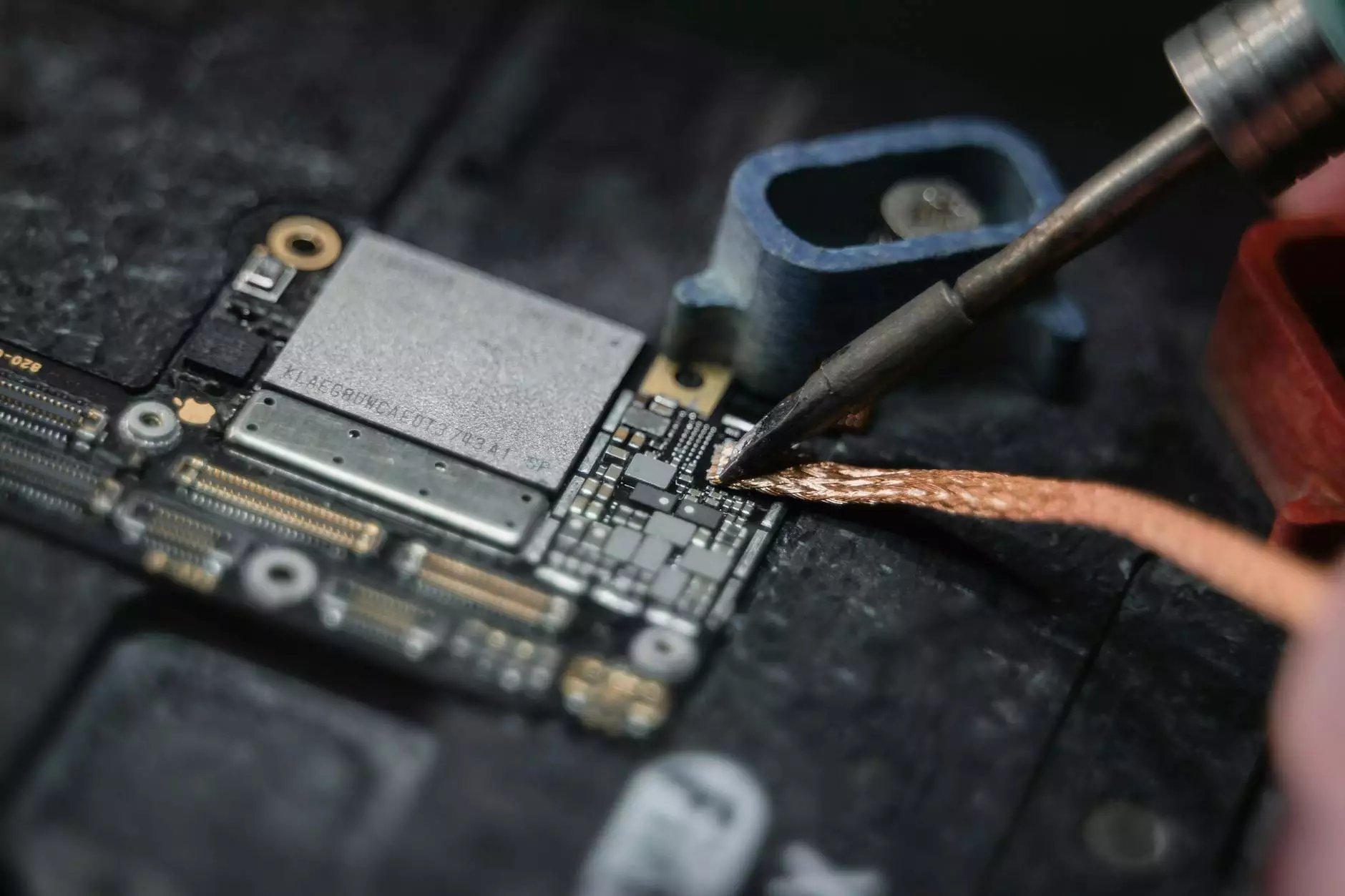

Strategy #1: Proper Equipment Setup and Preparation

In order to achieve successful PCB rework and repair, it is essential to have a well-equipped workstation. Here are a few key considerations:

- Work Area: Ensure you have a clean, well-lit and properly grounded workspace to carry out rework and repair tasks.

- Tools and Equipment: Invest in high-quality soldering irons, desoldering stations, hot air rework stations, magnifying tools, and other necessary equipment to efficiently handle PCB rework and repair.

- Anti-static Precautions: Always use anti-static wrist straps, mats, and other appropriate accessories to prevent ESD damage during the repair process.

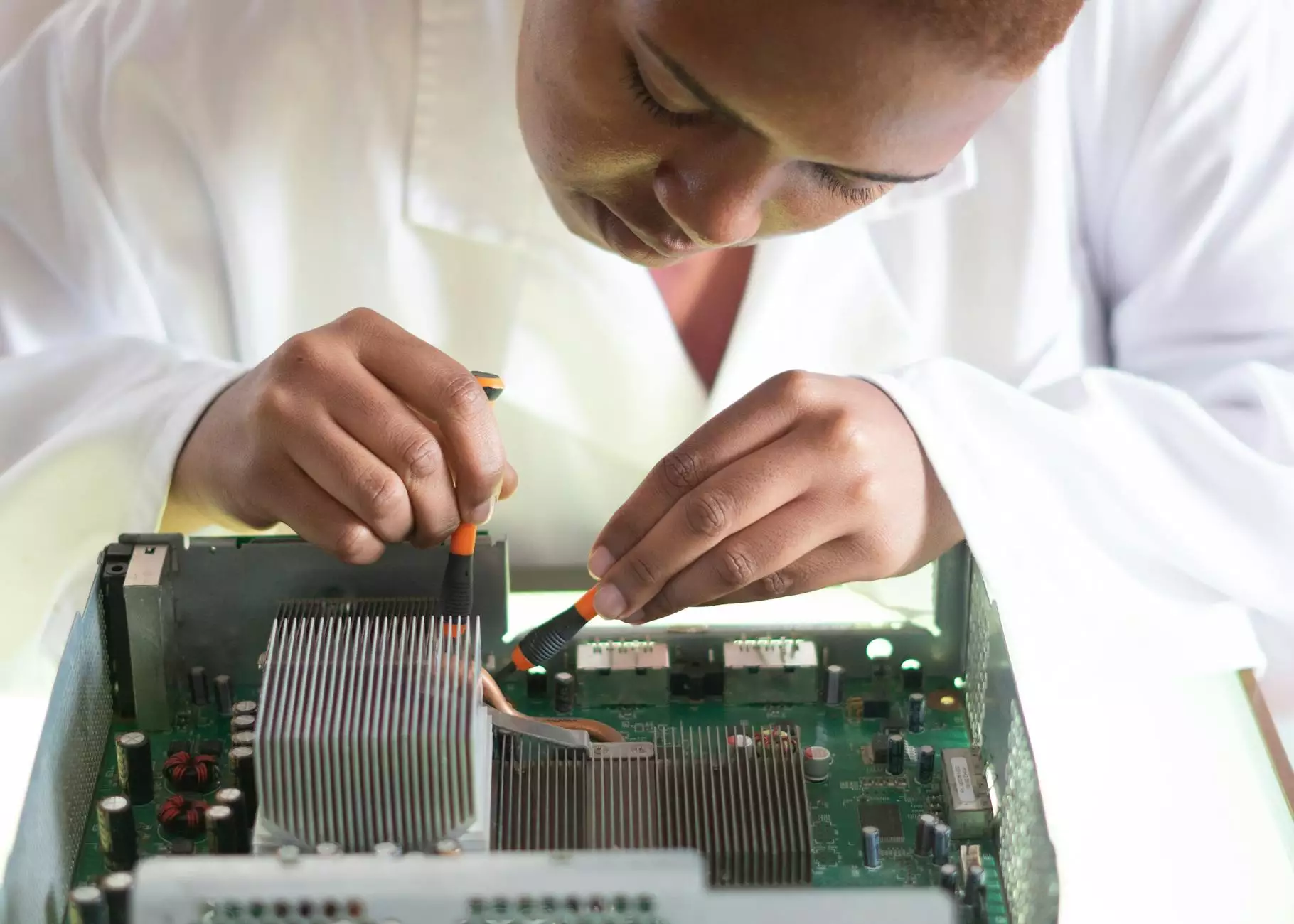

Strategy #2: Adequate Component Removal and Replacement

Proper handling and replacement of components play a crucial role in successful PCB rework and repair. Follow these steps:

- Component Removal: Use appropriate desoldering techniques such as hot air rework and desoldering wick to safely remove faulty components without damaging the surrounding area.

- Component Replacement: Ensure that replacement components are compatible, properly aligned, and securely soldered onto the PCB. Use high-quality solder and flux for reliable connections.

- Inspection and Testing: Thoroughly inspect the repaired PCB, checking for any solder bridges, cold joints, or other defects. Perform functional testing to verify the effectiveness of the repair.

Strategy #3: Troubleshooting and Diagnostic Techniques

Successful PCB rework and repair require accurate troubleshooting and diagnostic skills. Here are some valuable techniques:

- Circuit Analysis: Utilize circuit diagrams, schematics, and datasheets to identify the specific components and connections relevant to the faulty area.

- Signal Tracing: Use multimeters, oscilloscopes, and other testing instruments to trace signals, identify voltage irregularities, and pinpoint the root cause of the issue.

- Component Testing: Test individual components using appropriate tools to determine their functionality and isolate any faulty parts that require replacement.

- Repair Documentation: Maintain detailed documentation throughout the repair process, including notes, diagrams, and findings. This information can be invaluable for future reference and troubleshooting.

Conclusion

Mastering the strategies discussed in this guide will greatly improve your ability to effectively rework and repair PCBs. By following proper equipment setup, component removal and replacement techniques, as well as employing troubleshooting and diagnostic skills, you can ensure successful repair outcomes. Remember, consistent practice, attention to detail, and continuous learning are the key to becoming an expert in PCB rework and repair. Stay committed, and you will be equipped to handle a wide range of PCB repair challenges.