Navigating the World of Electronics Standards: Why IPC Standards Are Crucial for Your Business

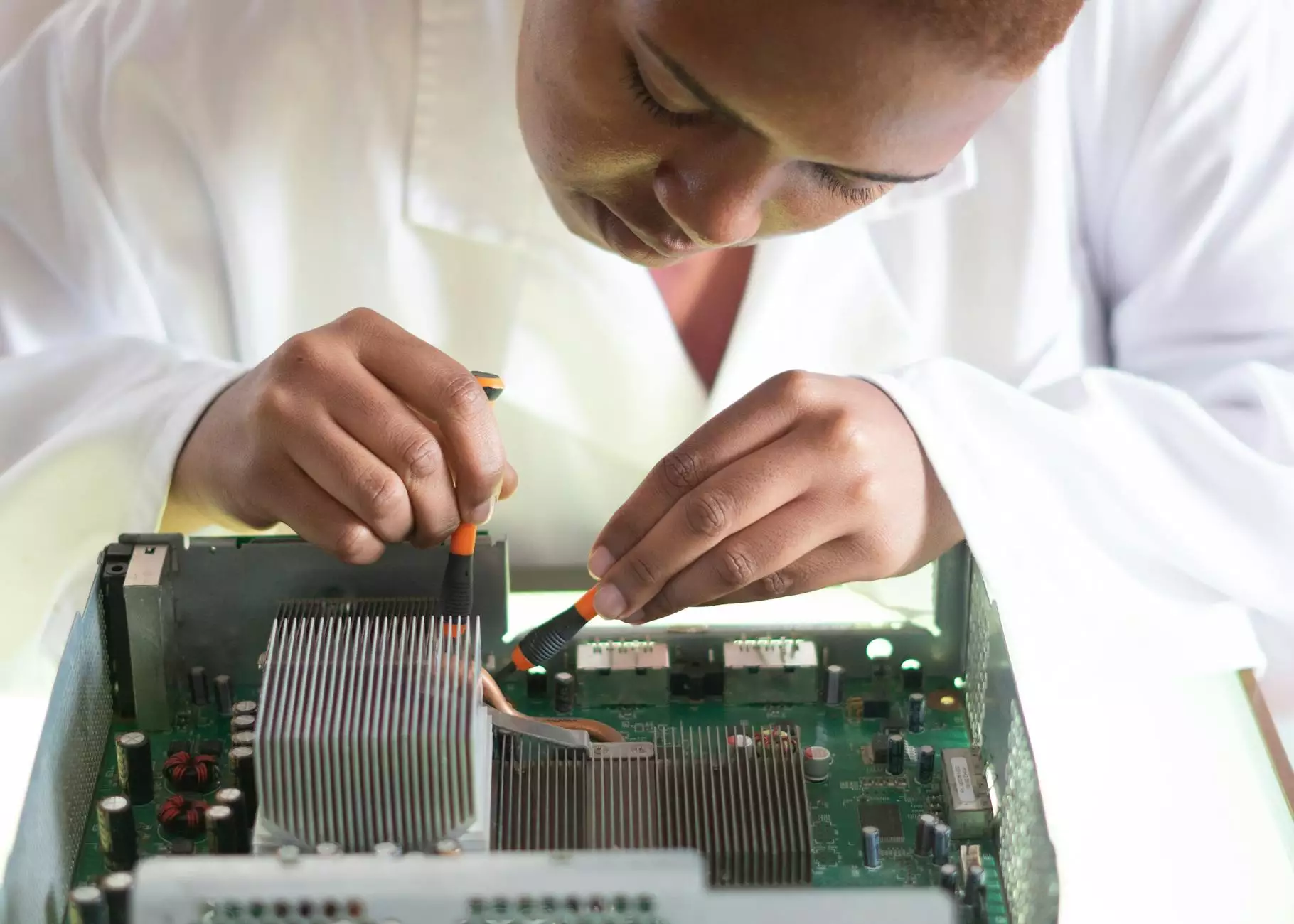

Welcome to our comprehensive guide on navigating the world of electronics standards. In today's rapidly evolving technological landscape, staying up-to-date with the latest industry standards is crucial for businesses operating in the electronics sector. In this article, we will delve into the importance of IPC standards and explain how they can help your business thrive.

The Significance of IPC Standards

IPC, or the Institute for Printed Circuits, is a global organization that develops and maintains industry standards for the electronics assembly, interconnect, and packaging processes. These standards, collectively known as IPC standards, define the necessary requirements and guidelines for ensuring the quality, reliability, and consistency of electronic products.

By adhering to IPC standards, businesses can effectively streamline their manufacturing processes, reduce errors, enhance product performance, and mitigate risks. IPC standards encompass a wide array of areas, including design, materials, assembly, testing, and more. Complying with these standards not only improves the overall efficiency of operations but also instills confidence in customers, suppliers, and partners.

Understanding the Hierarchy of IPC Standards

IPC standards come in various forms, each serving a specific purpose and catering to different stages of the electronics manufacturing process. Let's take a closer look at the hierarchy of IPC standards:

IPC-A-610: Acceptability of Electronic Assemblies

IPC-A-610 is the most widely recognized standard for inspecting and accepting electronic assemblies. It provides clear criteria for classifying electronic products based on their acceptability levels. This standard covers everything from solder joints and component mounting to cleanliness and markings, ensuring consistent quality throughout the assembly process.

IPC-6012: Qualification and Performance Specification for Rigid Printed Boards

IPC-6012 focuses on the qualification and performance requirements of rigid printed circuit boards (PCBs). It outlines specific criteria for material selection, fabrication methods, dimensional tolerances, and physical and electrical properties of PCBs. Adhering to this standard helps prevent defects, reduces the risk of failure, and extends the lifespan of electronic devices.

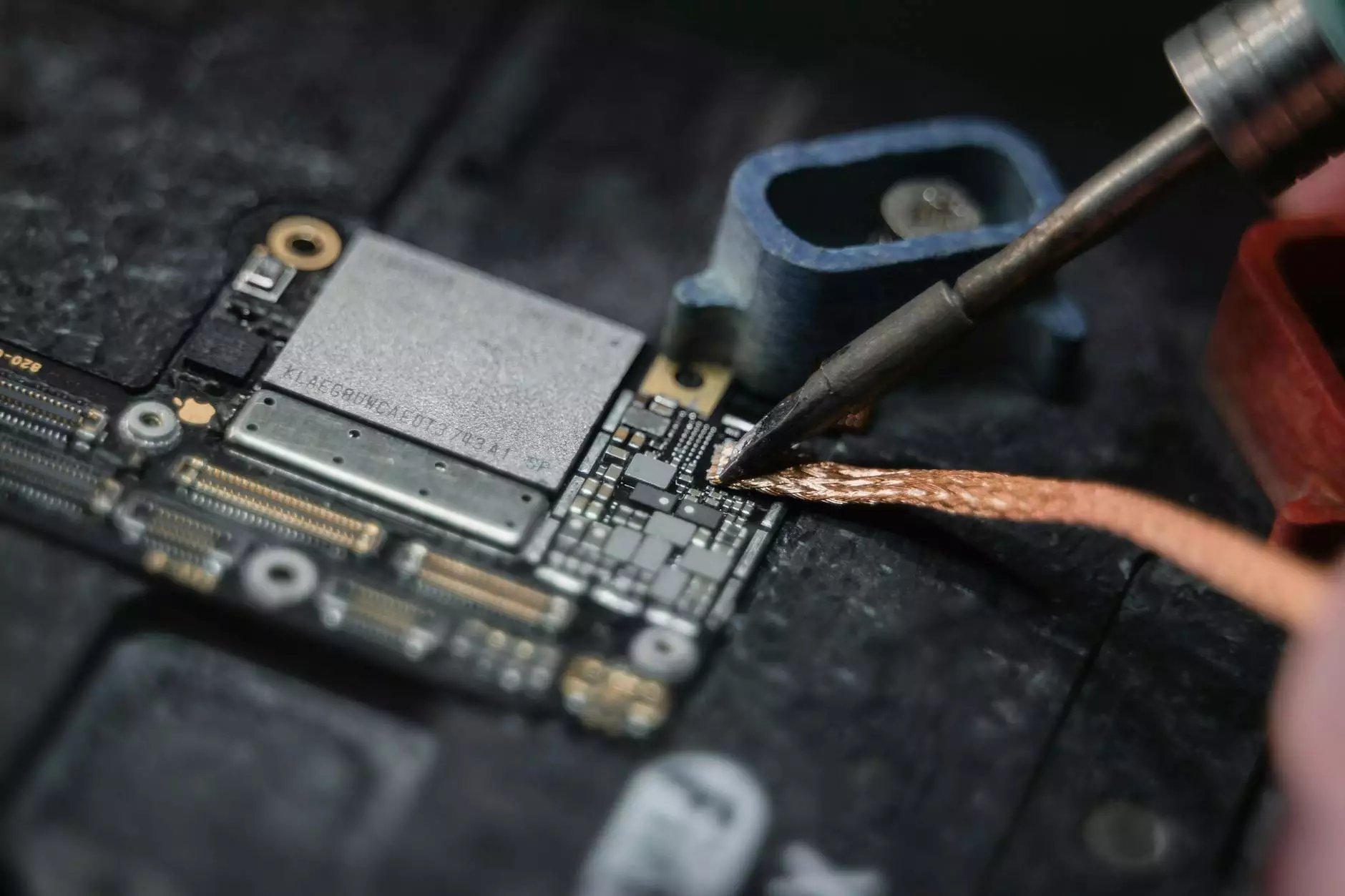

IPC-J-STD-001: Requirements for Soldered Electrical and Electronic Assemblies

IPC-J-STD-001 sets the industry benchmark for soldering processes and requirements for electrical and electronic assemblies. This standard covers the entire soldering process, including solder materials, methods, cleanliness, and inspection criteria. It ensures high-quality solder joints that meet the performance and reliability standards demanded by modern electronic devices.

The Advantages of Complying with IPC Standards

There are numerous advantages to adopting IPC standards within your business:

- Enhanced Product Quality: Adhering to IPC standards enables you to consistently produce high-quality electronic products that meet stringent industry requirements.

- Reduced Costs: By minimizing errors, rework, and product failures, IPC standards help minimize costs associated with scrap, warranty claims, and customer returns.

- Improved Customer Satisfaction: IPC standards ensure that your products function as intended, leading to satisfied customers who trust your brand.

- Increased Competitiveness: Demonstrating compliance with IPC standards can give your business a competitive edge over competitors by showcasing your commitment to quality and reliability.

- Streamlined Supply Chain: IPC standards provide common guidelines, making it easier to collaborate with suppliers, partners, and subcontractors, reducing misunderstandings and enhancing efficiency across the supply chain.

- Regulatory Compliance: IPC standards often align with regulatory requirements and international standards, ensuring your business remains compliant with industry regulations.

Choosing the Right Partner for IPC Compliance

When it comes to navigating the world of electronics standards, partnering with an experienced and knowledgeable service provider is crucial. At SEOinSydney, we offer comprehensive SEO services tailored to businesses in the Business and Consumer Services industry. Our team of experts is well-versed in IPC standards and can guide you through the compliance process, helping you optimize your operations and achieve industry recognition.

With our assistance, you can stay ahead of the competition, identify potential risks, and unlock opportunities for growth. Contact us today to learn more about our services and how we can elevate your business through IPC compliance.

Contact SEOinSydney for Unmatched Expertise

If you're ready to take your business's electronics standards to new heights, turn to SEOinSydney. We are dedicated to helping businesses like yours establish a strong online presence through effective SEO strategies and content creation. Reach out to us today to kickstart your journey towards industry excellence.