FAQs: Clarification and Interpretation of a Variety of IPC Standards

Introduction

Welcome to our website, where we provide comprehensive FAQs, clarification, and interpretation of a variety of IPC standards. As a leading provider of SEO services in the business and consumer services industry, we understand the importance of ensuring businesses and consumers have a clear understanding of IPC standards.

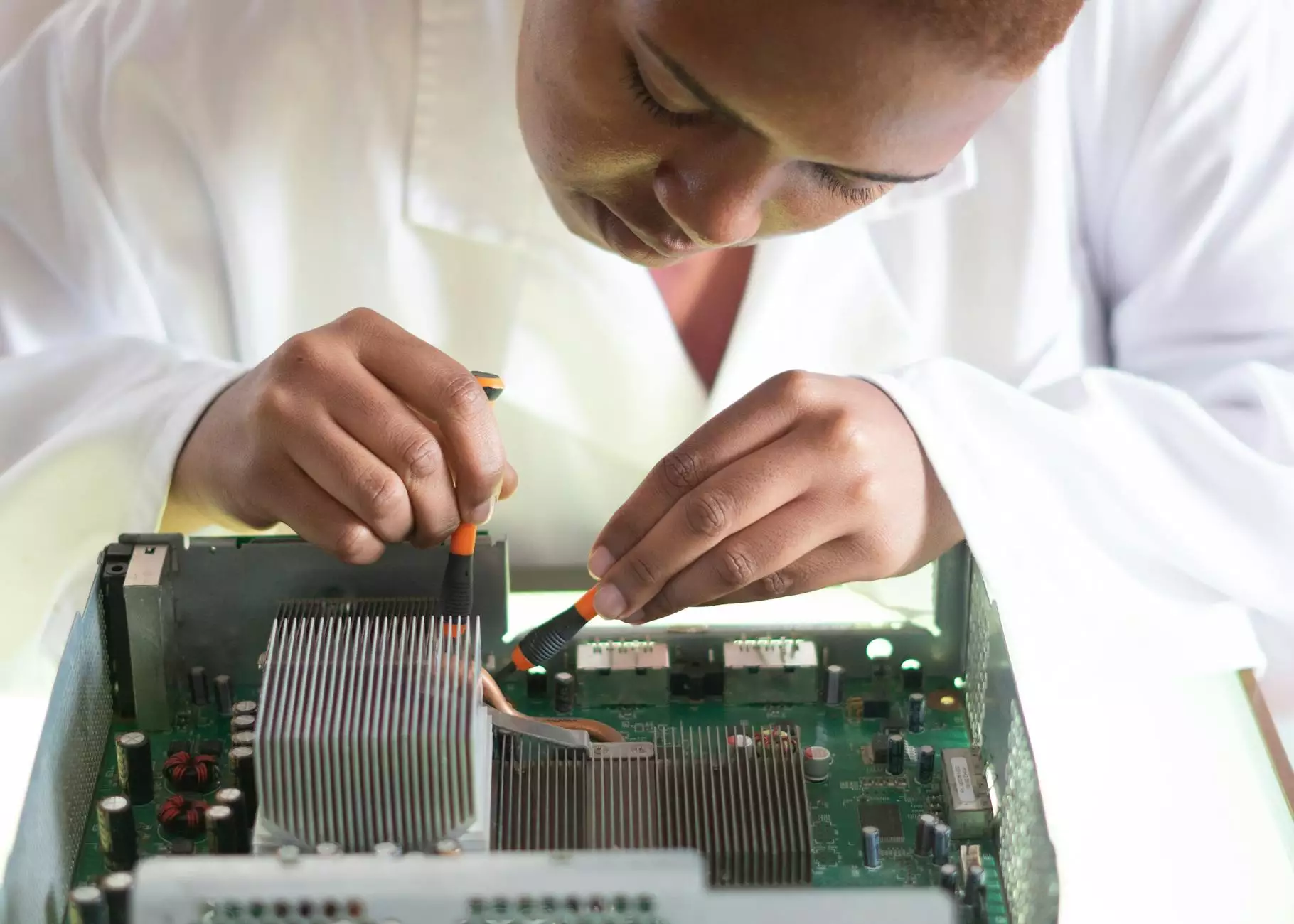

What are IPC Standards?

IPC stands for the Institute for Printed Circuits. IPC standards are a set of guidelines and industry-recognized specifications that govern the design, fabrication, and assembly of printed circuit boards and electronic assemblies. These standards ensure quality, reliability, and consistency in the electronics manufacturing industry.

Importance of Clarification and Interpretation

Clarifying and interpreting IPC standards is crucial for businesses and consumers to operate within regulatory requirements and to ensure the efficiency, reliability, and safety of electronic products. Our SEO services offer expert guidance and comprehensive understanding of IPC standards, helping you navigate through complex technical specifications.

FAQs: Your Questions, Answered

1. What are the common IPC standards that businesses should be aware of?

There are several crucial IPC standards that businesses need to be familiar with, including:

- IPC-A-600: Acceptability of Printed Boards

- IPC-A-610: Acceptability of Electronic Assemblies

- IPC/WHMA-A-620: Requirements and Acceptance for Cable and Wire Harness Assemblies

- IPC-7711/7721: Rework, Modification, and Repair of Electronic Assemblies

- IPC-J-STD-001: Requirements for Soldered Electrical and Electronic Assemblies

2. How do IPC standards ensure quality and reliability in electronic manufacturing?

IPC standards provide guidelines for materials, processes, and inspections throughout the electronic manufacturing lifecycle. These standards define criteria for acceptable quality levels, ensuring consistency and reliability in the production of electronic devices. By adhering to IPC standards, manufacturers can minimize defects, improve product performance, and increase customer satisfaction.

3. Can you provide examples of IPC standard requirements?

Certainly! Here are a few examples of requirements found in various IPC standards:

- IPC-A-600 specifies the criteria for assessing the acceptability of printed circuit boards, including dimensions, hole attributes, surface finishes, and conductor spacing.

- IPC-A-610 outlines the acceptability criteria for electronic assemblies, covering soldering conditions, component mounting, cleanliness, and marking and labeling requirements.

- IPC/WHMA-A-620 defines requirements for cable and wire harness assemblies, including cable preparation, crimping, soldering, insulation, and testing.

- IPC-7711/7721 provides guidelines for rework, repair, and modification of electronic assemblies, including component removal, cleaning, reballing, and soldering techniques.

- IPC-J-STD-001 lays out the requirements for soldered electrical and electronic assemblies, covering solder materials, flux application, solder joint criteria, and visual acceptance criteria.

4. Are there specific IPC standards for different industries or applications?

Indeed, IPC standards cater to specific industries and applications to address unique requirements. Examples of industry-specific IPC standards include:

- IPC-6012: Qualification and Performance Specification for Rigid Printed Boards

- IPC-6015: Qualification and Performance Specification for Organic Multichip Modules

- IPC-6018: Qualification and Performance Specification for High Frequency (Microwave) Printed Boards

- IPC-4101: Specification for Base Materials for Rigid and Multilayer Printed Boards

5. How can your SEO services assist businesses and consumers in understanding IPC standards?

Our dedicated team of SEO experts specializes in providing comprehensive guidance, clarification, and interpretation of IPC standards. We offer:

- In-depth analysis of IPC standard requirements and their practical implications

- Clear explanations of technical jargon and complex concepts

- Guidance on IPC certification processes and compliance

- Tailored recommendations for achieving IPC standard compliance

- Expert advice on resolving IPC standard-related challenges and issues

Conclusion

When it comes to IPC standards, having a thorough understanding of the requirements is crucial for businesses and consumers. With our SEO services, you can access comprehensive FAQs, along with in-depth clarification and interpretation of a variety of IPC standards. Let our expert team help you navigate the complexities of IPC standards, ensuring compliance and promoting the success of your electronic manufacturing endeavors.