Interpreting IPC-A-600 Requirements for Annular Rings and Laminate Cracks

Introduction

Welcome to SEO in Sydney's comprehensive guide on interpreting IPC-A-600 requirements for annular rings and laminate cracks in the printed circuit board (PCB) manufacturing industry. As leaders in the field of SEO services for businesses in the realm of business and consumer services, we aim to provide detailed insights to help you understand the quality control aspects of PCB production.

Understanding IPC-A-600

IPC-A-600 is a widely recognized standard developed by the Association Connecting Electronics Industries (IPC) for the acceptance criteria of PCBs. It specifies the requirements for several critical aspects of PCB manufacturing, including annular rings and laminate cracks. Let's dive deeper into these particular requirements.

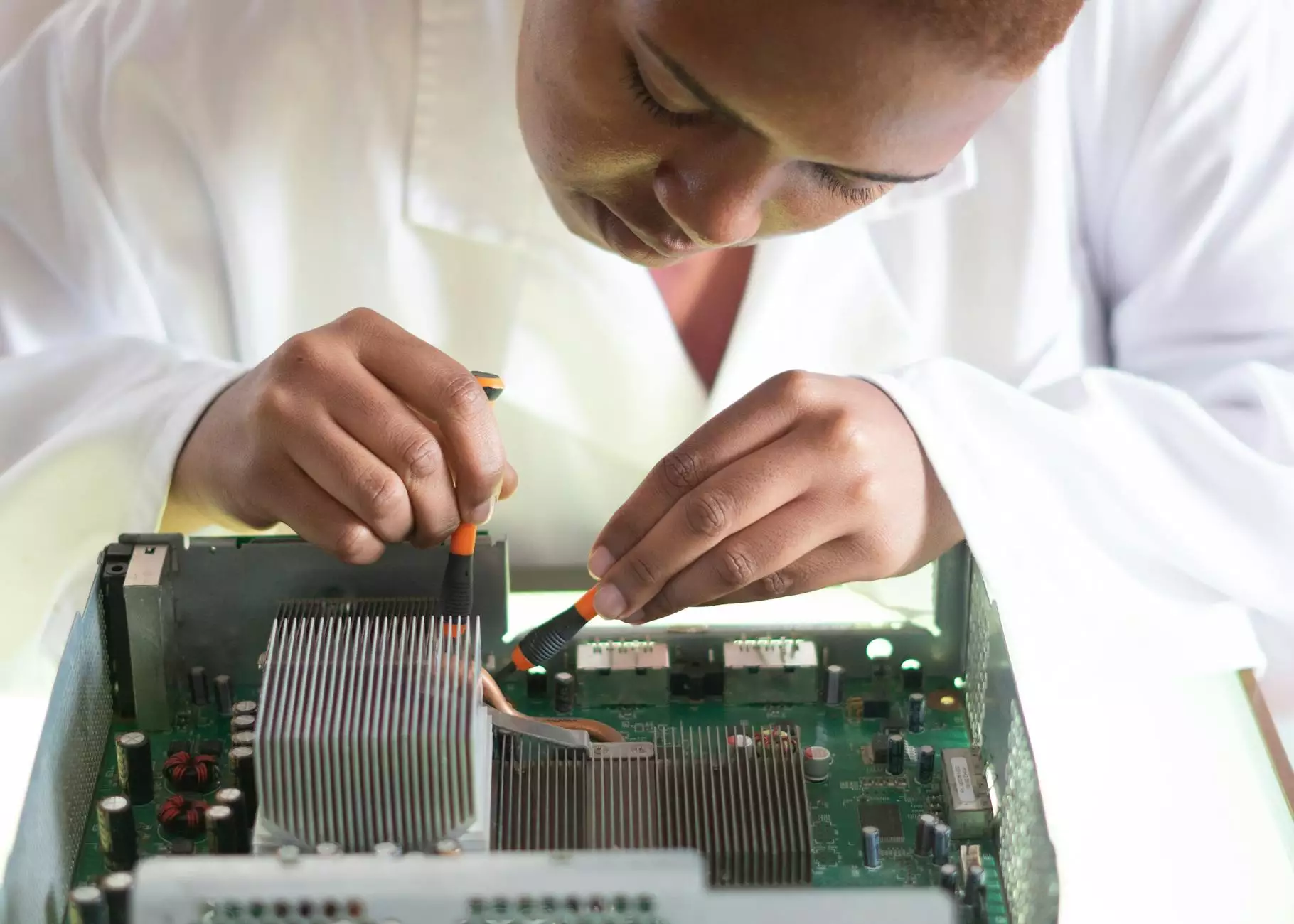

An Overview of Annular Rings

Annular rings refer to the copper rings surrounding the vias or plated through-holes (PTHs) on a PCB. The size, shape, and quality of these rings play a crucial role in ensuring reliable connections for components and circuitry. Understanding the IPC-A-600 requirements for annular rings is essential for maintaining high-quality PCB production.

IPC-A-600 Classifications

IPC-A-600 classifies annular rings into three main categories: Class 1, Class 2, and Class 3. Each class has different acceptance criteria, with Class 3 being the most stringent. While Class 1 includes less critical applications such as general consumer electronics, Class 3 is applicable to high-reliability products where failures can have severe consequences.

Acceptance Criteria

The IPC-A-600 standard defines specific acceptance criteria for annular rings based on factors like size, shape, and the presence of any voids or cracks. These criteria ensure that the annular rings meet the desired quality and functionality requirements. Compliance with these criteria ensures reliable construction and optimal electrical performance of the PCB.

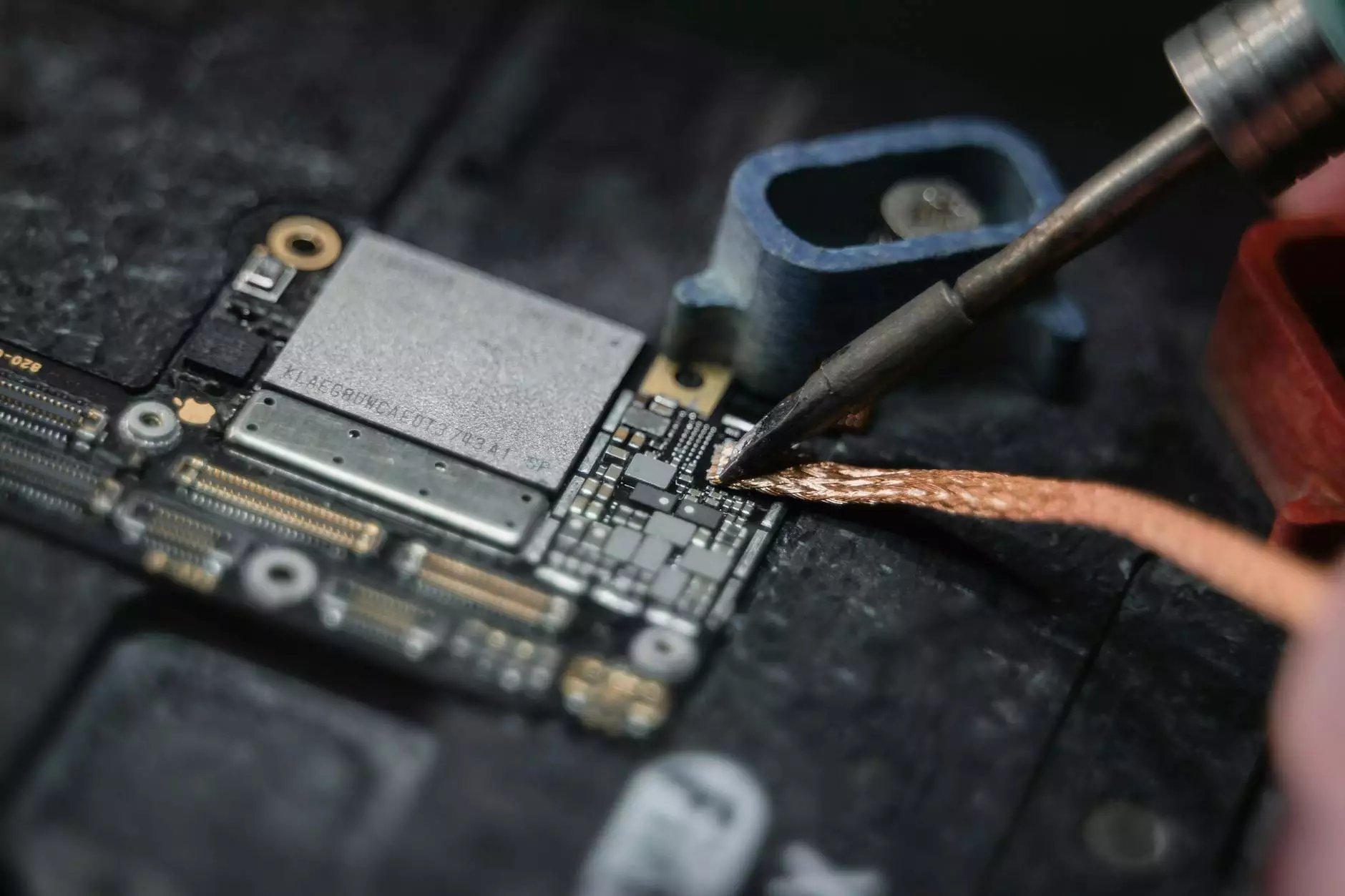

An Insight into Laminate Cracks

Laminate cracks are fractures or separations that occur within the layers of a PCB's base material. These cracks can compromise the structural integrity and electrical functionality of the board. Understanding the IPC-A-600 requirements for laminate cracks is crucial for identifying and addressing potential issues in PCB manufacturing.

Classification of Laminate Cracks

Similar to annular rings, IPC-A-600 classifies laminate cracks into different categories based on their severity and impact on performance. The three main classes are Class 1, Class 2, and Class 3. The acceptance criteria become progressively stricter as we move from Class 1 to Class 3.

Crack Identification and Inspection

The IPC-A-600 standard outlines various visual and dimensional inspection methods to identify and classify laminate cracks accurately. These inspection procedures help manufacturers assess the presence, size, and location of cracks. Understanding these methods is essential for ensuring compliance with the specified acceptance criteria and producing high-quality PCBs.

The Role of Quality Control in PCB Manufacturing

Quality control is a vital aspect of PCB manufacturing, ensuring that every board produced meets the required standards. Following the IPC-A-600 requirements for annular rings and laminate cracks is crucial for maintaining consistency in quality and reliability.

Effective Quality Control Practices

Implementing effective quality control practices involves thorough inspection, testing, and monitoring at various stages of the PCB manufacturing process. Adhering to the IPC-A-600 standards is essential to identify and rectify any deviations or defects that may arise during production.

Benefits of Compliance

Complying with the IPC-A-600 requirements for annular rings and laminate cracks brings numerous benefits to both PCB manufacturers and end-users. These include enhanced product reliability, reduced chances of failure, improved customer satisfaction, and increased trust in the brand's offerings.

Conclusion

In conclusion, understanding and interpreting the IPC-A-600 requirements for annular rings and laminate cracks are essential for achieving high-quality PCB manufacturing. SEO in Sydney, a trusted provider of SEO services in the business and consumer services sector, aims to empower businesses with the knowledge they need to excel in their industry. Make sure to implement these insights to ensure your PCBs meet the desired standards and surpass customer expectations.