SolderTips: Gold Removal and Wave Soldering vs Hand Soldering

The Importance of Efficient Soldering Techniques

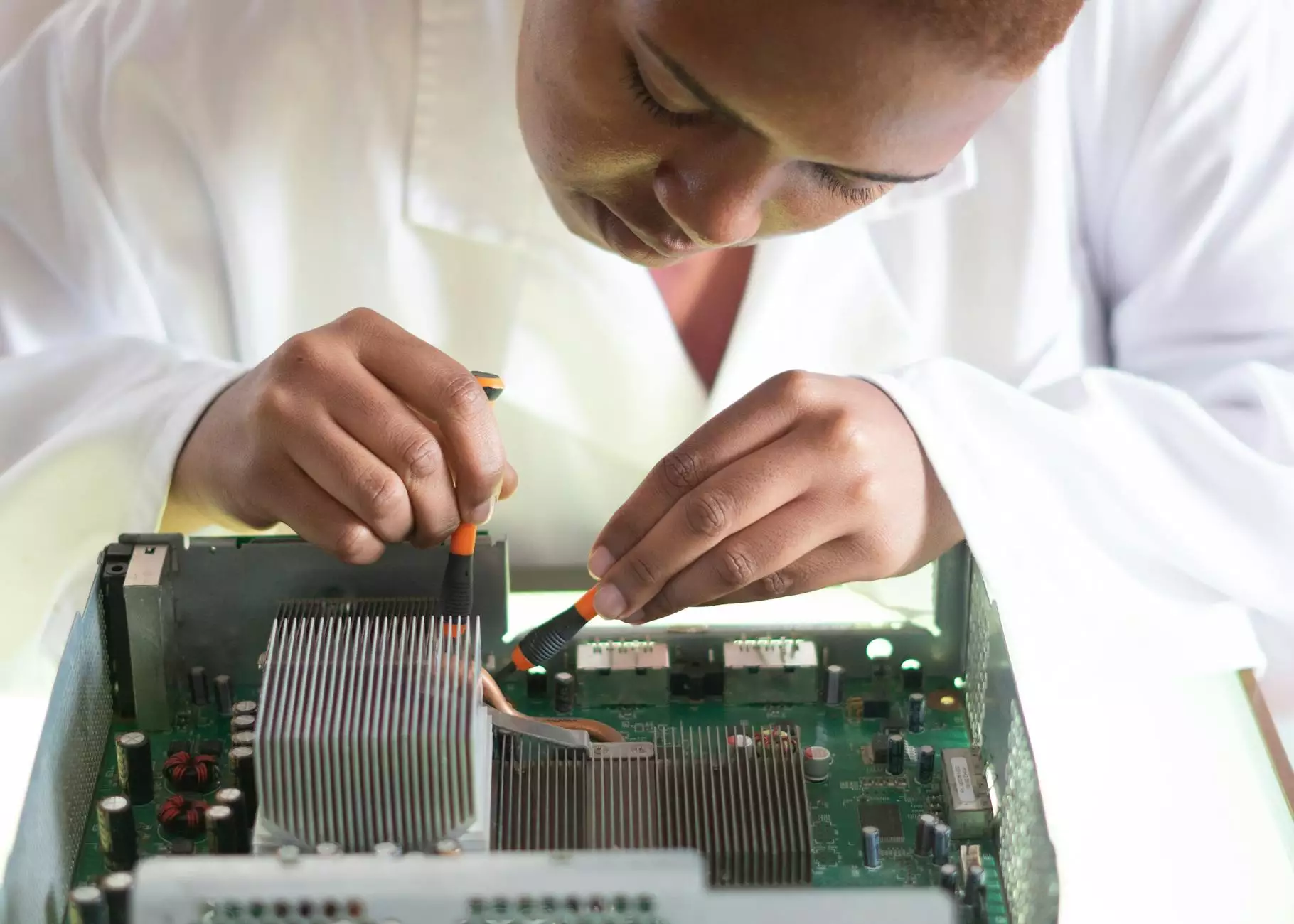

Soldering plays a crucial role in the electronics and manufacturing industry. Whether you are working with consumer electronics, industrial equipment, or any other electronic device, efficient soldering techniques are essential to ensure reliable and long-lasting connections.

Gold Removal: Why is it Necessary?

Gold removal is often required during the soldering process, especially when dealing with electronic components that have gold-plated connectors. The gold plating needs to be carefully removed before soldering to ensure proper adhesion and to prevent any issues that may arise from soldering directly on the gold surface.

Methods for Gold Removal

When it comes to gold removal, there are primarily two common methods used - wave soldering and hand soldering.

Wave Soldering: The Pros and Cons

Wave soldering is a highly efficient technique that allows for simultaneous soldering of multiple connections. It is typically used in mass production settings where speed and accuracy are crucial. The process involves creating a wave of molten solder that flows over the circuit board, creating solder joints at the desired locations.

One of the major advantages of wave soldering is its ability to remove gold plating through the solder wave action, eliminating the need for separate gold removal procedures. This saves time and ensures consistent results. However, wave soldering may not be suitable for delicate components that require precise manual handling.

Keywords: wave soldering, efficient soldering, gold removal, mass production, solder joints

Hand Soldering: The Benefits and Limitations

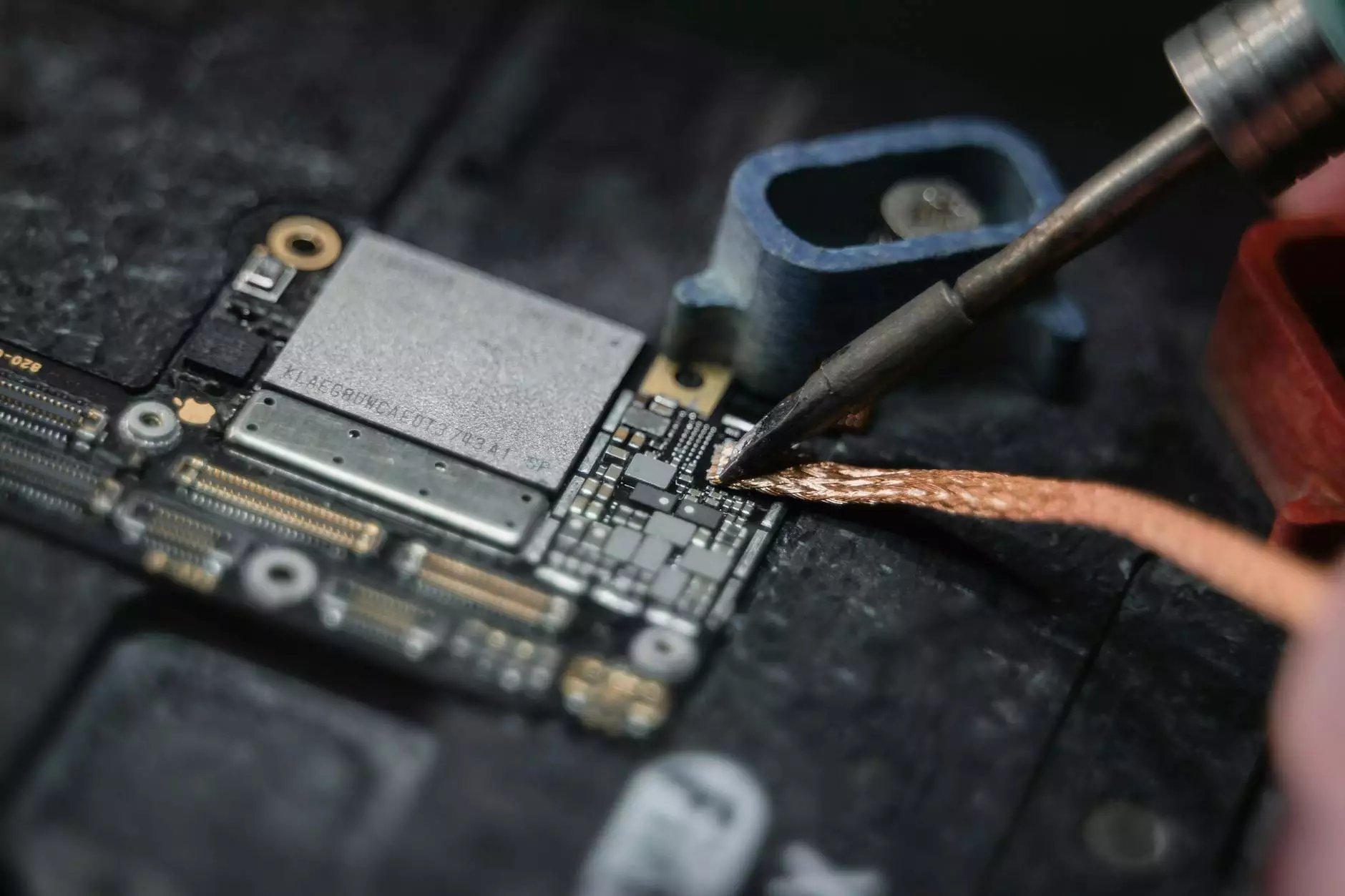

Hand soldering, as the name suggests, involves the manual application of solder to the desired locations. It allows for precise control over the soldering process and is suitable for delicate components and low-volume production.

When it comes to gold removal, hand soldering requires an additional step of manually removing the gold plating before soldering. This can be done using specialized tools and techniques to ensure the gold is completely removed without causing any damage to the underlying components.

Keywords: hand soldering, precise control, delicate components, gold removal, low-volume production

Choosing the Right Technique

The choice between wave soldering and hand soldering depends on various factors such as the nature of the project, production volume, component requirements, and time constraints. Both techniques have their advantages and limitations, so it's important to evaluate your specific needs before making a decision.

Factors to Consider

- Project Scale: For large-scale production, where speed and efficiency are paramount, wave soldering may be the preferred choice.

- Component Sensitivity: Delicate components that require careful handling may be better suited for hand soldering to minimize the risk of damage.

- Production Volume: High-volume production often favors wave soldering due to its automation capabilities, while low-volume production can benefit from the precision of hand soldering.

- Technical Expertise: Hand soldering requires skilled operators who can ensure proper gold removal and soldering techniques, while wave soldering relies more on machinery.

Conclusion

In the world of electronics manufacturing, efficient soldering techniques are critical for reliable connections. Gold removal is often necessary before the soldering process, and both wave soldering and hand soldering offer viable options depending on the specific requirements of the project.

By carefully considering factors such as project scale, component sensitivity, production volume, and technical expertise, you can make an informed decision on which technique best suits your needs. Remember, each technique has its own strengths and weaknesses, so it is important to choose wisely to ensure high-quality results and efficient production processes.

For more information on soldering techniques and gold removal, feel free to browse our website or contact our team of experts.

Contact Us for Expert Soldering Services

If you need assistance with soldering, gold removal, or any other soldering-related services, our team at [Your Company Name] is here to help. With years of experience and expertise, we provide top-notch soldering services for various industries and applications. Contact us today for reliable and efficient soldering solutions.